Contact Us

Tel : +86-18668608946

Fax : +86-0717-3902201

Email : aw0024@szautoware.com

Add : West section of Jinping Avenue,Dangyang,Hubei province,China

EPC for Kumasi Oil Depot in Ghana,Africa

Project Overview

This oil depot is a strategic repository of Ghana.The supervisory party is the Indian International Supervision Company.The reserve has a total of 12 oil storage tanks.Five are inner floating roof tanks and seven ordinary vault tanks,The total capacity is: 119,000 cubic meters.There are three intermediate tanks for unloading transition.Each tank has a capacity of 100 cubic meters.There are 6 groups of unloading cargo platforms.There are 12 loading cranes.

System structure Introduction

The entire system uses an open, distributed system architecture.Do "distributed control, centralized management, information sharing",The monitoring management system specifically includes:

Tank capacity measurement subsystem

Using EMERSON's high-precision radar level gauge,High static pressure transmitter,Multi-point thermometer and TANKMASTER tank capacity calculation software.

Data acquisition and monitoring management subsystem

Using the GE PAC 3i controller and its process I/O set,2 sets of upper computer system,Use GE CIMPLICITY HMI industrial configuration software.

Process control instrument

Adopting domestic top electric cut-off ball valve,3051 transmitter,E+H tuning fork level switch,French FM spiral wheel flowmeter and so on.

Fire alarm subsystem

The fire system adopts Beijing Lida fire alarm button and controller,The flammable gas alarm system adopts Shenzhen Tean Company ES2000 series products.

Transceiver monitoring and management subsystem

Adopting Hongyi AWZC series loading management system and its software,On-site equipment includes:French FM loading flowmeter,EMERSON 788 electro-hydraulic CNC valve,Overfill Grounding protector.etc

Network and remote service sharing system

Data monitoring data transmission to the production management office and customs.

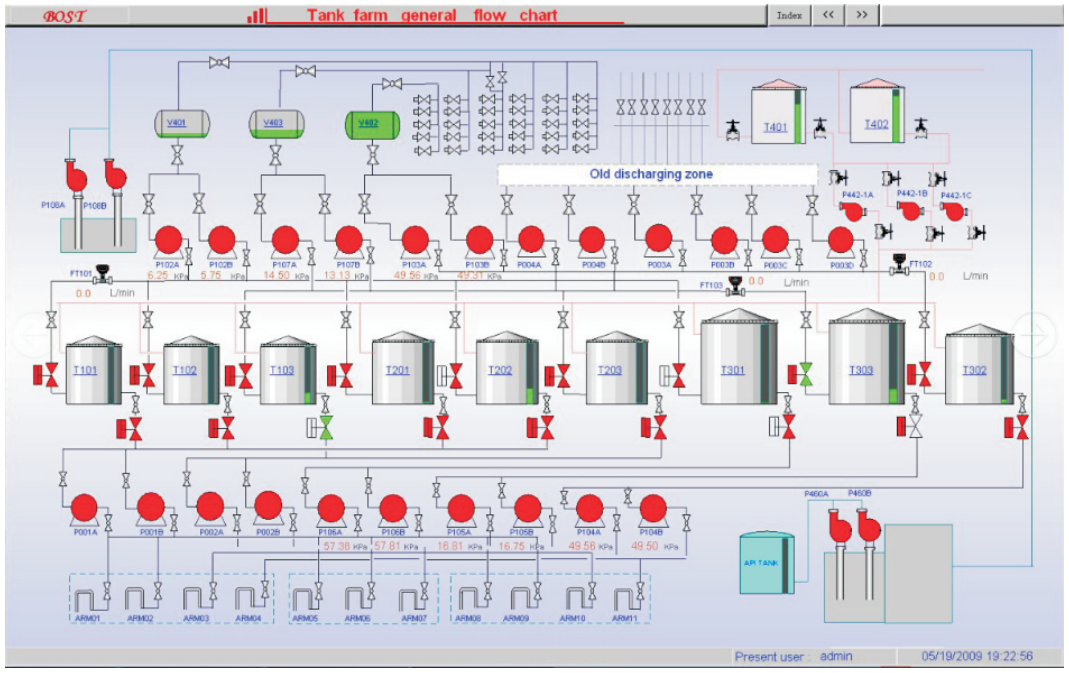

System screenshot

The system is closely integrated with the automatic control of the tank area.And can display the liquid level, temperature and even pressure changes of the tank in real time in the form of a graphical interface:

Tank map

The tank zone partition map can display the corresponding parameters of the zoned tank in real time.And the corresponding production operations can be performed on the partition:

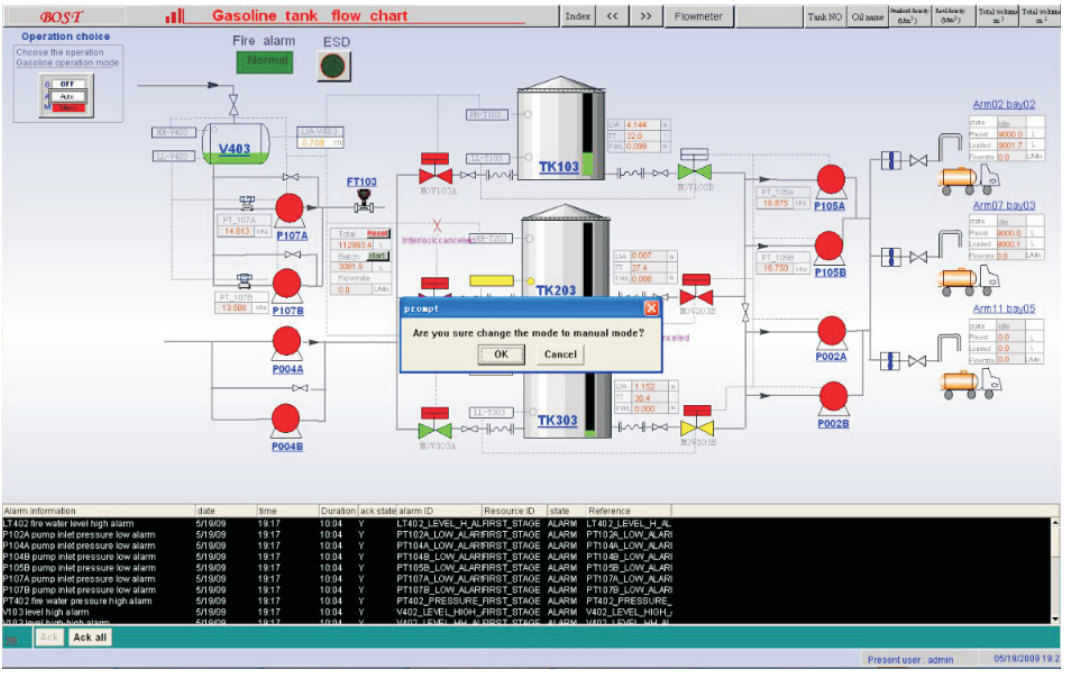

Tank map

System screenshot

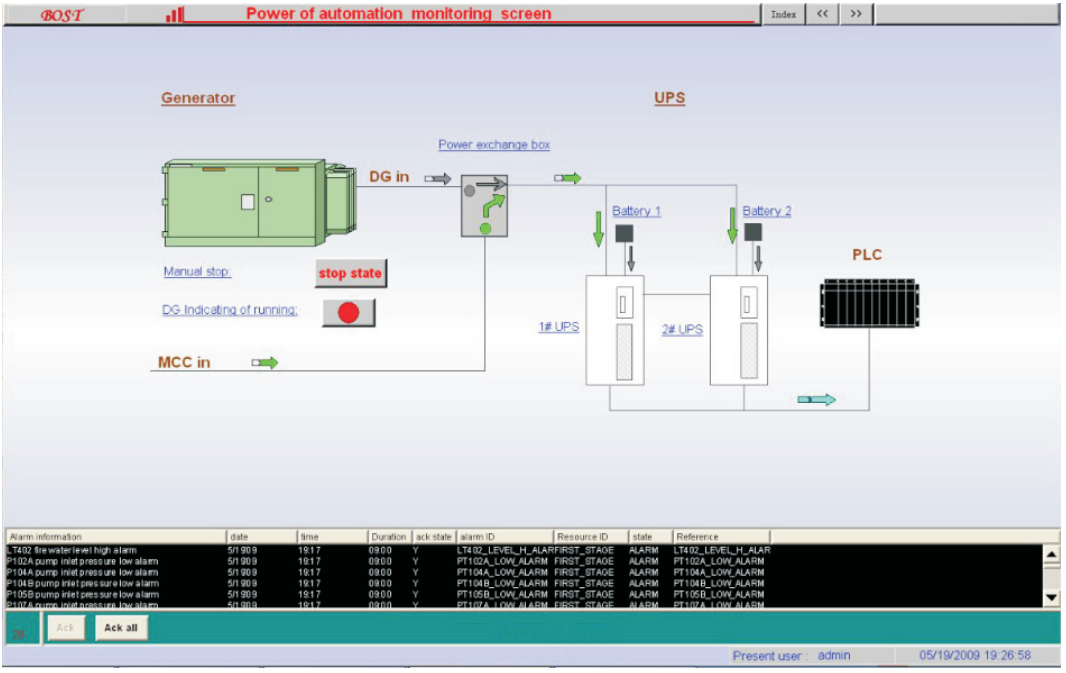

Power supply redundancy management system,The entire system is powered by the UPS in the event of a power outage.The UPS is redundant,If the UPS supports the time to the warning level,The generator will automatically start to supply power.The power supply structure diagram screen is as follows:

Power supply system screen

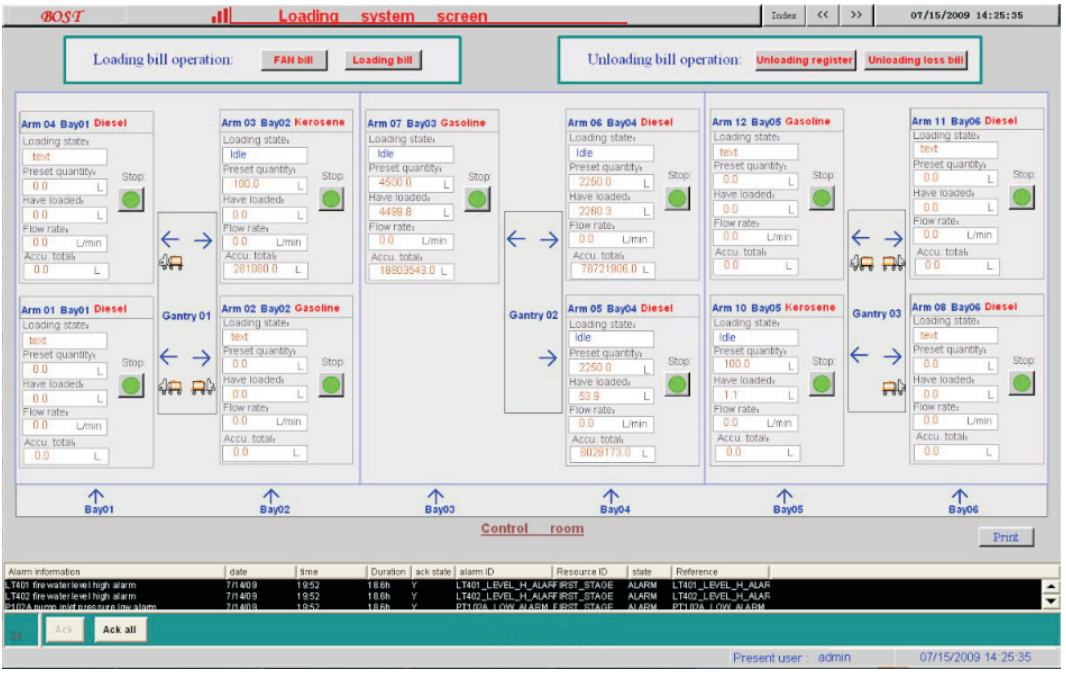

Send and receive oil control screen,Data statistics,Send and sell oil reports in real time, etc.The picture is as follows:

Send and sell oil control screen

System screenshot

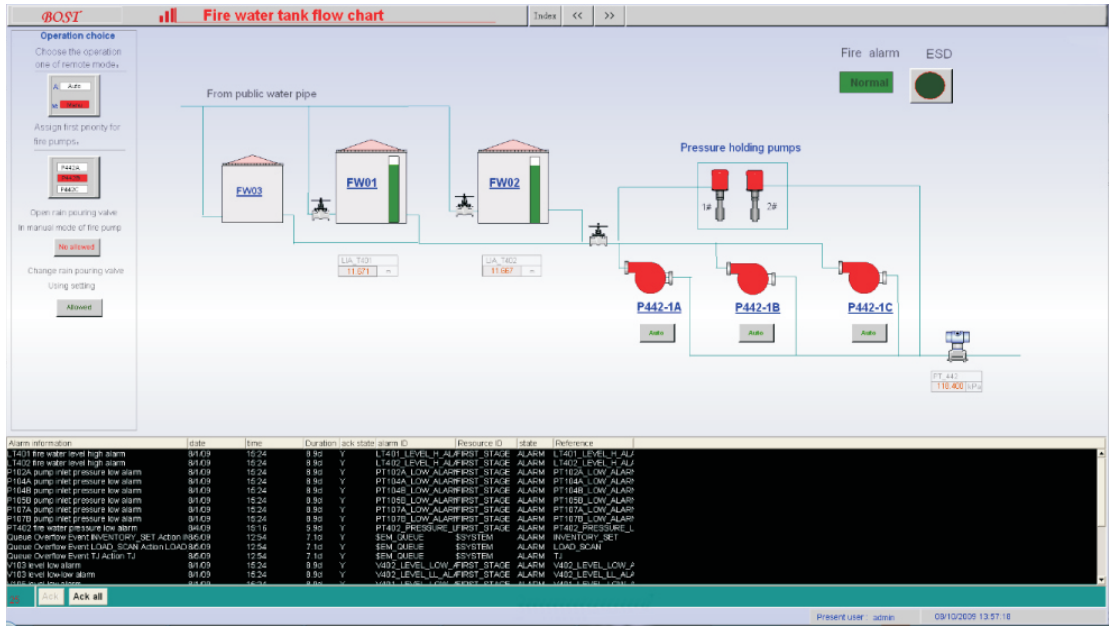

The fire pump station screen monitors the parameters of the fire pumping station, etc. The screen is as follows:

Fire monitoring screen

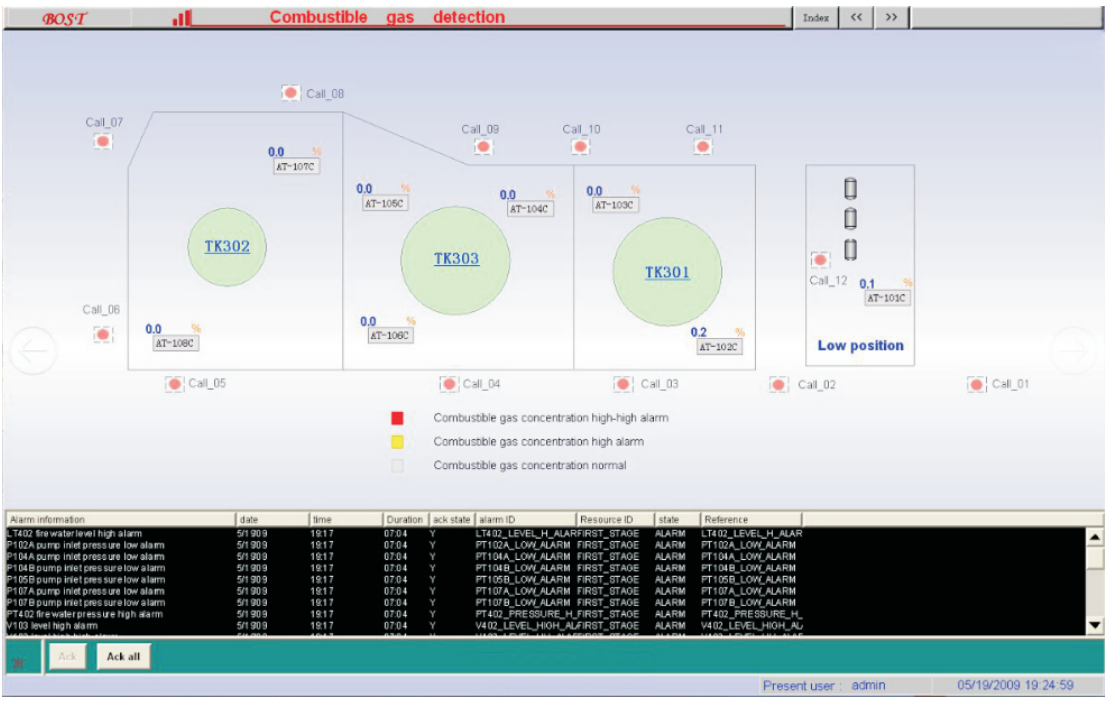

The combustible gas monitoring screen monitors the flammable gas detectors in each zone.Monitor its alarm status,The picture is as follows:

Combustible gas monitoring screen

System screenshot

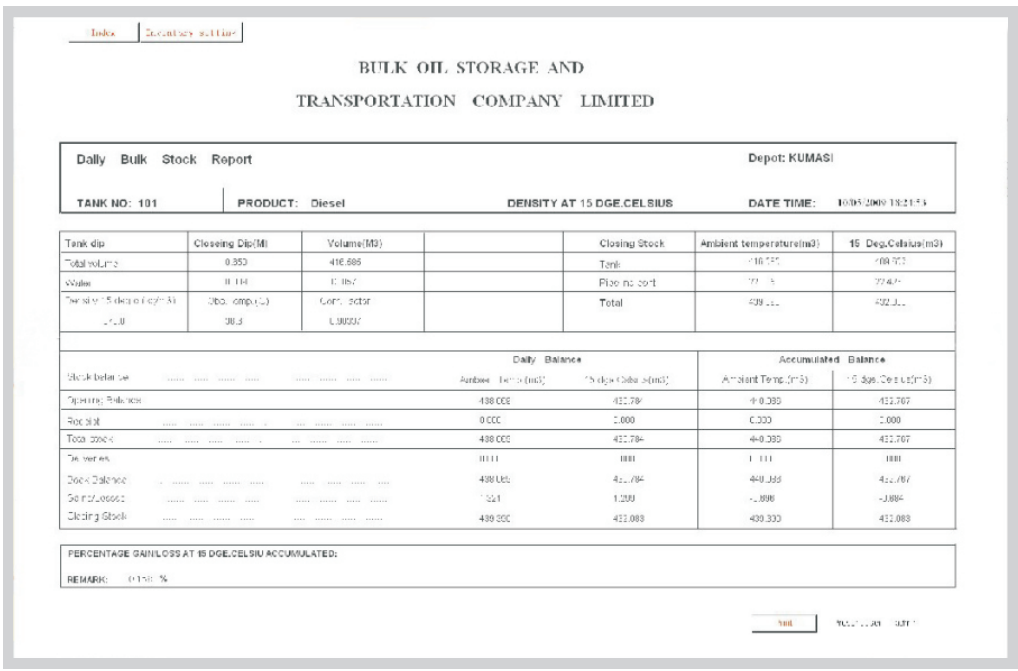

The tank area data report performs data statistics and report printing on the entire monitoring system.The program file screens started by each monitoring computer are as follows:

Data report manager screen

Calculate the loss of the tank capacity, calculate the loss of each tank and oil in the tank area,The sample screen is as follows:

Tank and oil loss calculation screen

EN

EN

RU

RU