Hot-melt butt joint method of loading arm swivel joint

When carrying out the hot-melt butt joint of the loading arm joint, we must follow the correct construction steps to operate. Only in this way can the quality and service life of the product be better improved, so what are the specific construction methods?

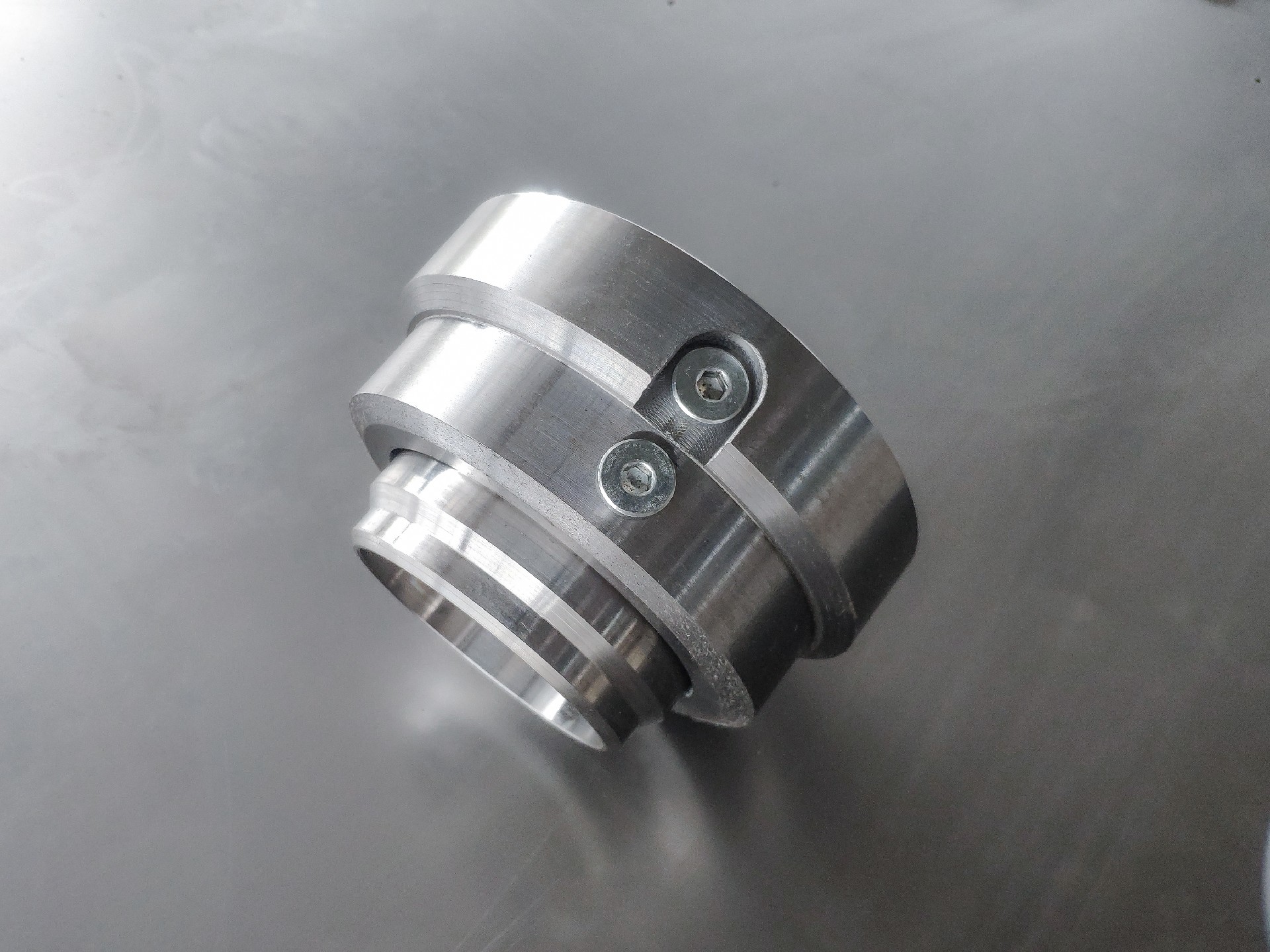

1.The connecting ends of the connecting parts at both ends should protrude a certain free length from the welding machine fixture, and straighten the two corresponding connecting parts so that they are on the same axis, and the wrong edge should not be greater than 5% of the wall thickness of the loading arm swivel joint.

2.After the heating is completed, the connecting piece should be quickly detached from the heating tool, and the uniformity and melting of the heating surface of the connecting piece to be inspected should be checked.

3.Use uniform external force to make the connection surface of the rotating joint of the loading arm completely contact, and turn the flange to form a flange.

4.The joint has smooth and symmetrical burring along the circumference of the pipe section, and the depth of the low part of the burring is not lower than the outer surface of the pipe section.

5.Remind everyone: heat the fuser in the range of 220 ± 5 ℃, and wait for the fuser indicator to show a red light, which means that it is in the state of heat preservation before the welding operation of the loading arm swivel joint.

6.When the swivel joint of the loading arm is docked, it must be noted that it meets the requirements of the corresponding international standards, and the quality of its appearance must be checked. Safety.

EN

EN

RU

RU