- Inquiry

Product description

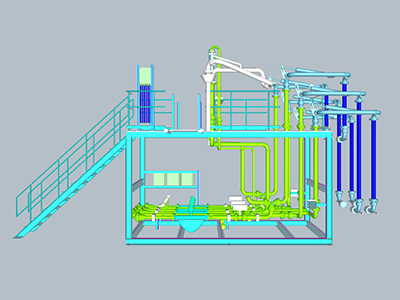

Skid-mounted means to fix a group of equipment on a chassis made of angle steel or I-steel, which can be moved and placed in place with skid bars and modern lifting equipment. Skid-mounted is a form of a combination of equipment frame and equipment.The skid-mounted refers to the integration of the batch controller, flowm eter ,valves, pipelines, auxiliary equipment,loading arm, intermediate connectors and cables, bridges, etc. on an integral steel structure platform, with only process connection ports and control power supplies reserved. And the communication interface, this integral part is called the skid-mounted.

Product feature

Flexible, small size

Skid-mounted equipment is generally optimized in the factory, so it is small in size. The skid-mounted equipment is used to make it a whole, and its movement and relocation are more convenient.

High integration ratio, easy installation and maintenance.

The skid-mounted integrates batch controller, flow meters, valves, pipelines, auxiliary equipment, loading arm, intermediate connectors and cables, bridges, etc., which is convenient for on-site installation and easy for overall maintenance.

Save on-site installation trouble, low cost, short construction period, high standardization, less error, and material saving

The skid-mounted saves the cumbersome and manufacturing time of traditional on-site process installation and instrument installation. It is more convenient to make and test in the factory, and it is more convenient to rectify problems when found, and the quality can be guaranteed.

Comparison of skid-mounted and traditional on-site installation

Contrast content | Traditional on-site installation | skid-mounted type |

Installation method | Many on-site procedures, inconvenient communication between equipment suppliers and installation units; poor protection of valuable instruments, long construction period, and poor quality | The whole equipment is integrated in the factory, and there is no cross-operation on site. The integrated product quality is guaranteed and the stability is good |

system debugging | There are uncertainties in the on-site installation of instrument problems, cable connection problems, and the suitability of each equipment installation, which increases the complexity and cycle of on-site debugging, and also leaves hidden dangers of system instability | The factory is highly integrated, eliminating the problems of instrument installation, cable connection and equipment installation. After factory testing, the system stability is guaranteed and the degree of standardization is high. |

cost | There is a lot of waste of on-site installation materials; the long period increases a lot of costs; the later on-site installation causes more hidden dangers and increases the later commissioning and maintenance costs | Stability and high standardization integration reduce installation costs, hidden dangers and subsequent commissioning and maintenance costs |

Type of skid-mounted:

The skid-mounted is divided into the following categories according to the different media and its loading and unloading methods during normal use:

◆ Bottom loading skid-mounted metering system

◆ Bottom loading skid-mounted metering system

◆ Movable loading skid-mounted

C-Activity skid-mounted(Activity skid-mounted are mostly special custom skid-mounted)

Technical Parameters

Customized according to requirements, no specific specifications |

Features show as mobile operation |

Generally small and compac |

The loading arm are mostly foldable |

EN

EN

RU

RU