- Inquiry

LNG loading skid mounted description

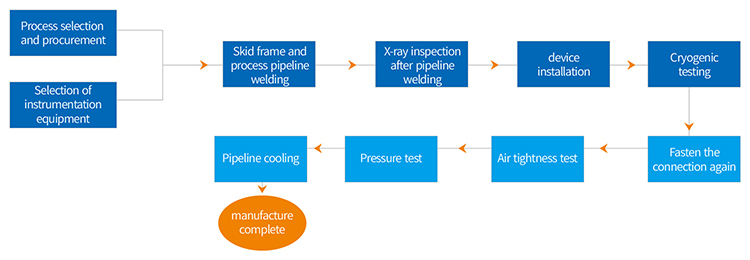

Based on the particularity of low temperature and related properties of LNG media, LNG skid-mounted instruments and equipment are integrated into a metal framework. The manufacturing steps are complex and are mainly divided into the following manufacturing steps:

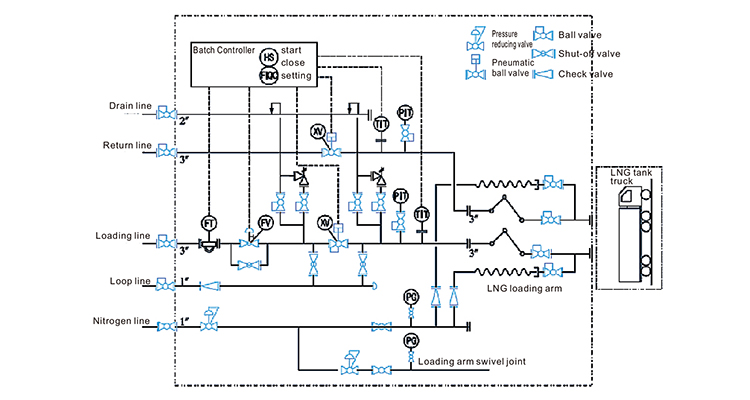

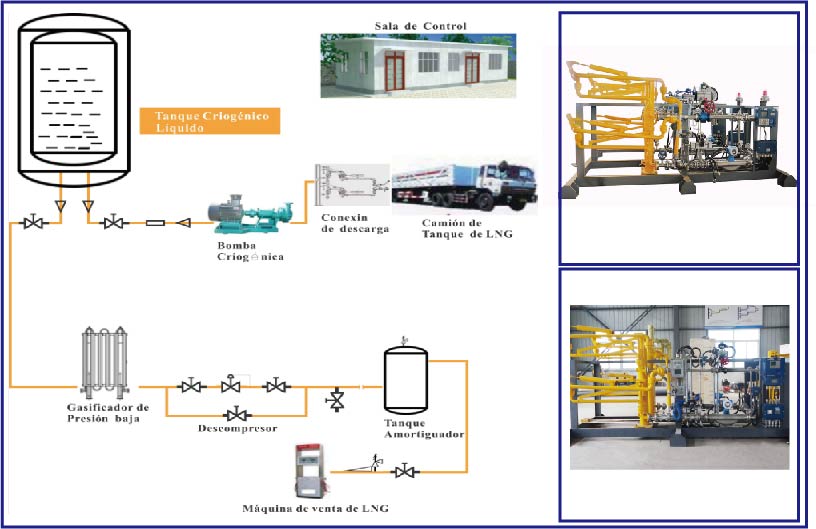

There are many process pipelines for LNG loading and the process flow is relatively complicated. The main pipelines are: loading line, return line, cold circulation line, bleed line, nitrogen line and so on. The flow chart is as follows:

Due to the complexity of the process, LNG loading has more automatic control instruments in its armor. It consist of loading arm with recovery pipe, flow meters, static grounding protector, pressure transmitters, Flow control valve, emergency shut-off valve, related piping and batch controller.

LNG equipment include bellow devices

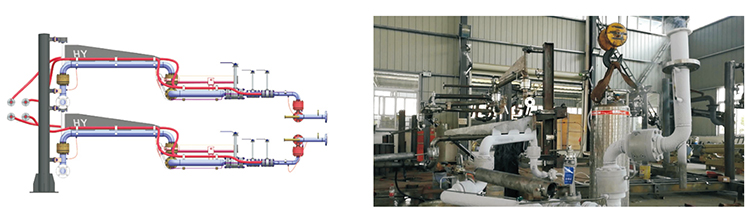

(1)LNG loading arm

The loading arm is the main equipment in the loading skid. The LNG loading arm adopts the double-armed column structure, and the two arms are installed up and down, respectively connected to the liquid and gas ports of the tank truck for LNG loading and BOG returning. The column support structure is beneficial for reducing the force of the rotating joint on the inner side of the arm, reducing wear and prolonging the life of the seal. Loading arm material 304/304 L (316 L in coastal areas), the material of the rotary joint must be sent to cryogenic processing to ensure its strength and wear resistance.

(2) LNG flow meter

(3) LNG Valve

(4) Temperature and pressure transmitter

(5) LNG batch controller

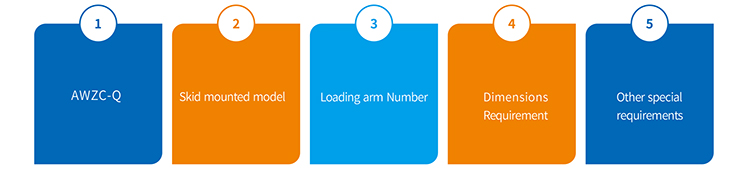

Skid mounted system selection

| Skid mounted model | |

| T | Top media loading skids |

| L0 | Bottom LNG Loading Skid |

| L1 | Bottom LPG like product loading skid |

| L2 | Sealed loading skid at the bottom of refined oil |

| S | Special customized loading skid |

| Loading arm Number | |

| S | Top media loading skid |

| D | Bottom LNG loading skid |

| T | Bottom LPG like product loading skid |

| F | Sealed loading skid at the bottom of refined oil |

| Dimensions Requirement | |

| A | standard |

| T | special |

| Other special requirements | |

| N | standard |

| T | special |

Technical Parameters

| LNG Loading process parameters | ||

| LNG pipeline (liquid phase) | LNG pipeline (Vapor phase) | |

| Operating temperature | -196℃/50℃ | -196℃/50℃ |

| Design temperature | -196℃/100℃ | -196℃/100℃ |

| Operating pressure | 0.55MPa | 0.1—0.55Mpa |

| Design pressure | 0.88Mpa | 0.78MPa |

| Design flow | 60m3/h | 200m3/h |

| Medium | LNG | NG |

| Density | 439.8kg/m3 | 2.41kg/m3 |

| Viscosity | 0.1237mpa.s | 0.005mpa.s |

| Diameter | 3” | 3” |

| Factory instrument air | 0.5-0.7Mpa (providing 0.6MPa air source in factory) | |

| Nitrogen purge | 0.4---0.8MPa (providing 0.7MPa air source in factory)Ambient temperature | Ambient temperature |

| Dangerous zone | ZONE1 | |

| Ex grade | Not less than EXdii BT4 | |

| Protection level | Not less than IP65 | |

EN

EN

RU

RU