- Inquiry

HONGYI-CZXT series unmanned weight management system is to use the equipment management server, highly integrated intelligent self-service terminal, LED large screen, voice system, IC card system, license plate recognition system, environmental camera system, infrared radiation and Barrier system and other equipment, each device is interconnected through industrial Ethernet. The equipment management server collects, stores and monitors information on the site, realizes information sharing and management, and effectively realizes unattended management of weighing scales. Not only can simplify the operation process, reduce the owner's operating personnel, but also can improve the production efficiency. At the same time, it effectively strengthens the supervision of on-site operations and effectively prevents the driver from cheating while operating.

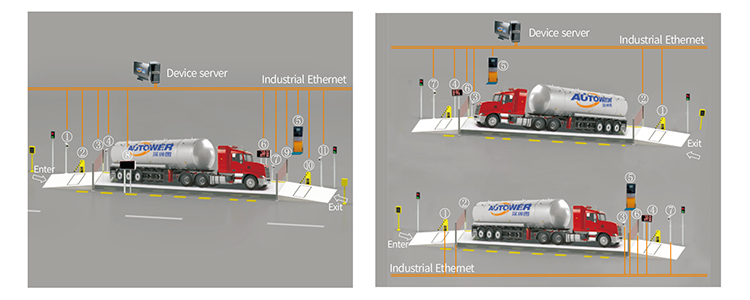

CZXT unattended weighing management system is divided into two-way and one-way weighing systems. The two-way weighing system has only one weighbridge. One weighbridge is used for both in and out (leather and wool weighing), and two unidirectional weighing systems are configured. Weighbridge, use one weighbridge (tare) and one weighbridge (gross). In these two types of management systems,

Using infrared radiation technology, collected by the device server prompts the driver to ensure that the parking is accurate;The following functions are mainly imaplemented:

1.Using high-definition license plate recognition technology, collected by the device server and check to determine the next step in the operation process;

2.Using intelligent barrier technology, the device server can implement automated actions according to the operation flow;

3.Using high-definition environment camera technology, collected by the device server real-time monitoring of the entire operation process to prevent the driver from having other unnecessary operations;

4.The use of LED large screen and voice technology, the device server to output relevant information to the LED screen and voice, Timely reminder driver on the ground scale operating specifications, improve the efficiency of the ground floor scale;

5.Using highly integrated intelligent self-service terminals, using IC card technology, swiping cards on self-service terminals to verify identity, save weighed information, and print bills. At the same time, IC can query historical records on self-service terminals through self-service terminals. It is equipped with a self-help function to enable timely communication between the driver and the owner's management personnel. The self-service terminal is equipped with an environmental camera system to effectively monitor the driver's operation process.

6.The unattended weighbridge weighing management system also has an individual weight weighing system, which effectively records the weight change of the driver during the entire operation process;

7.Equipment management server in addition to serving on-site equipment, while providing communication interfaces for other ERP, MIS, HMI and other systems to achieve data sharing and services;

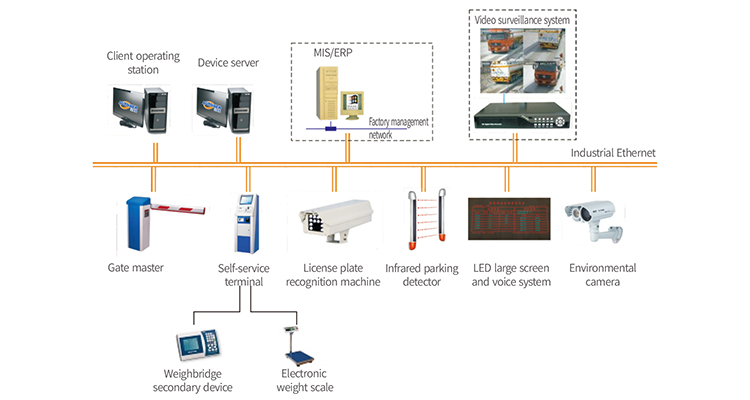

System instructions

1.The equipment server is installed in the control room, and it is connected with the main computer, self-service terminal, license plate recognition machine, infrared parking sensor, LED large screen and voice system, and environment camera through industrial Ethernet; collected and monitored by the equipment server. Connected equipment;

2.The client operation station is installed in the control room, installs the weighing management software, provides vehicle information management, data statistics, report query, report printing and other functions;

3.The self-service terminal is installed on the site and is used for the driver's on-site operation;

4.The weighbridge secondary-instrument and weight electronic said via serial communication and self-service terminal communication;

5.The device server can also be networked with other MIS and ERP systems to provide interfaces for other systems.

6.The environment camera can provide video signals to the hard disk video recorder to achieve video data display and storage;

Client station operation functions

The client operating station configures the commercial computer and installs the weighing management system software, which mainly implements the following functions:

1.System management function: It is mainly to add, modify, delete, etc. the management information, operation level, vehicle information, customer data, and IC card information of the system, query information, generate reports and print preview;

2.Monitoring function: Real-time monitoring of on-site ground scales, displaying current vehicle information, weighing, real-time video signals, etc.;

3.report statistics query function: according to the customer name, license plate information and other statistical pound records, generate reports and print preview;

4.bill printing function: according to the needs of the owners customized bill format, printed over the pound single;

Device Server Functions

Self-service terminal functions

The self-service terminal is equipped with a high-performance integrated industrial control computer. The industrial control computer has a large-screen touch screen, and human-computer interaction is achieved through a touch screen. Self-service terminals are also equipped with hardware devices such as bill printers and IC card readers, and self-service terminals. Client operating software is also installed on the system to achieve the following functions:

1.Networking function: In addition to networking with industrial Ethernet and equipment server, and self-service RS232/RS485 communication interface, the self-service terminal can realize the data collection of the ground scale and weight scale;

2.Operation function: The driver can realize data query, weighing operation, help operation, print operation and other functions through the touch screen;

3.Read the IC card function: built-in IC card reader, can be integrated with the owner's other IC card system to achieve the simplification of the process operation;

4.Report query function: According to the license plate number to query the weighing record, vehicle information;

System advantages

1.Optimize procurement and sales business processes, adopt IC card and network technology to realize the plan of loading and unloading truck business, and cooperate with IC-card system to realize vehicle information sharing from billing, entering factory, measuring, receiving and shipping, and leaving the factory, mutual verification of business links, and real-time logistics Monitor and make full use of information tools to improve the efficiency and control of logistics management.

2.Establish an informatized remote metering platform suitable for production, operation and management, and standardize, standardize, electronicize and integrate all metering and metering business data.

3.Realize the remote centralized measurement of truck scales, achieve balanced distribution and measurement of many tasks on the long-range, increase the anti-cheat function of the perfect system, make full use of the spare time, and improve the efficiency of measurement.

4.Improve overall measurement efficiency and reduce measurement costs.

5.Realize the seamless connection between unattended weighing system and other subsystems (quantitative loading system, ERP system, inspection system, etc.) to provide data for production and operation, cost settlement and logistics management. Information and other statistical weighing records, generate reports and print preview;

Applications

EN

EN

RU

RU