- Inquiry

Petrochemical Storage Terminal SCADA system

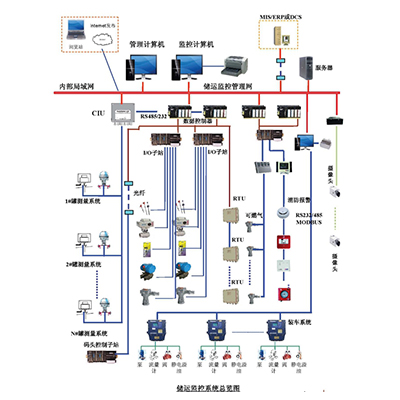

System structure & principle

SCADA(Supervisory Control And Data Acquisition) system means data acquisition and monitoring control system, SCADA system is a computer-based production process control and scheduling automation system to achieve data acquisition, display, network release, device control, measurement, parameter adjustment, and various types of signal alarm and other functions .

System Structure Composition

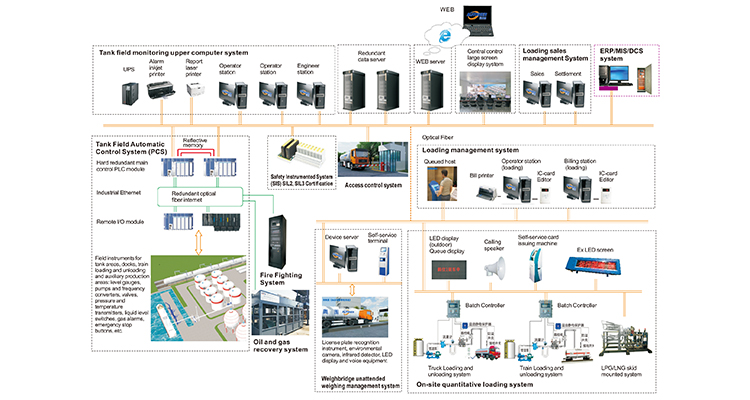

The petrochemical storage SCADA system is divided into tank level monitoring systems, vagon or vehicle loading unloading management systems, oil and gas recovery systems, fire alarm and fire protection systems, perimeter systems, access control IC-card system and other subsystems.SCADA system is divided into layers: storage and transportation system integrated management platform, main monitoring system, and on-site main instruments. Therefore, the scope as follows:

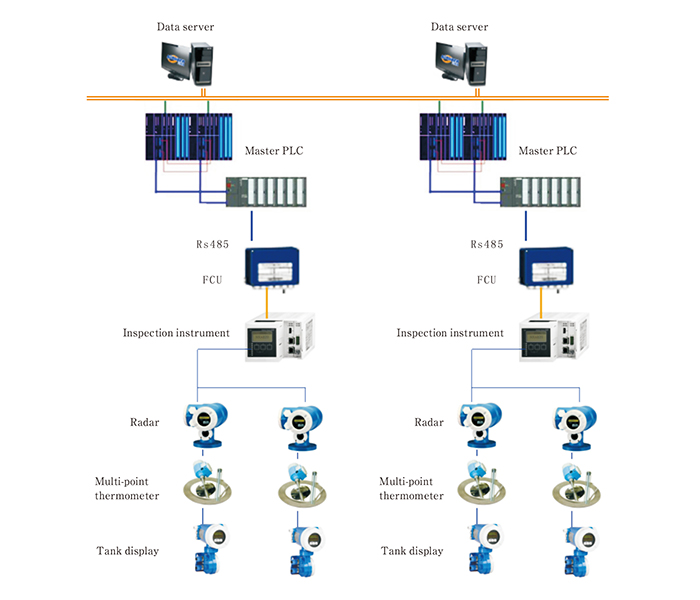

SCADA System structure

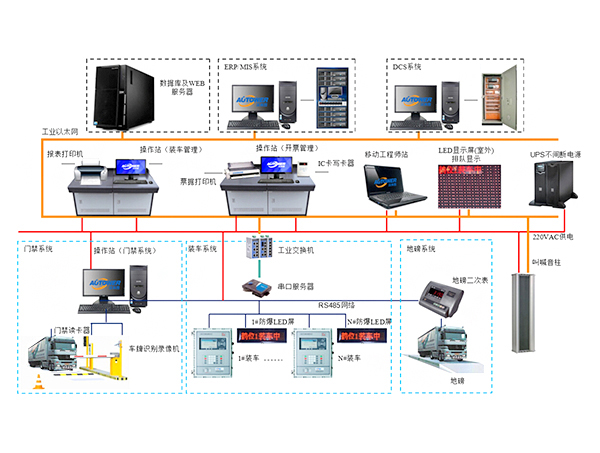

Configuration of Units in SCADA System

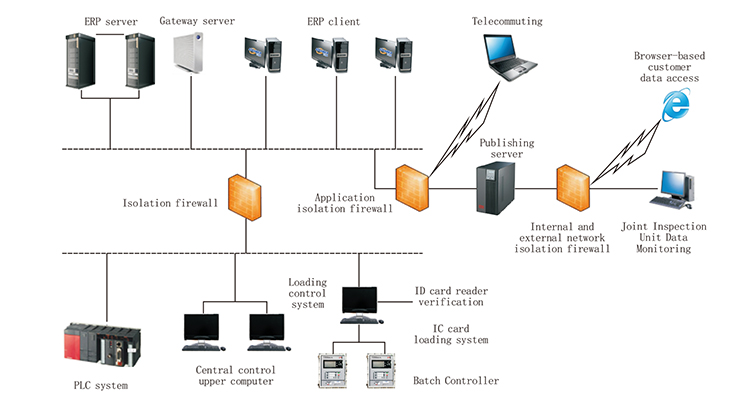

1. ERP or OA system

For the petrochemical storage features, Customized ERP or OA system, in the perochemical storage has a very good practicality

Netwoek structure diagram of petrochemical storage ERP system

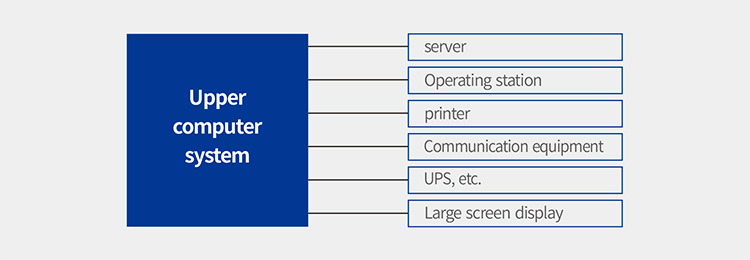

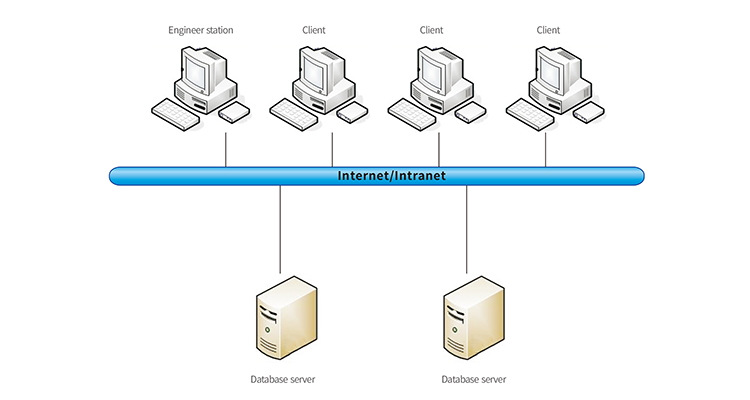

2.Upper computer system configuration and function

The upper computer system include

Standard structure is as follow

3. PLC or DCS, SIS core controller unit section

PLC core control unit usually use SIEMENS, GE, AB, etc.

For the storage system of large-scale projects, PLC generally requires the use of medium and large equipment, PLC main control equipment using a hard redundant dual-machine hot standby structure, CPU Modules, power modules, Ethernet modules, and networks are all configured in a redundant manner. Failure of any one master control device does not cause system defects, and the redundant switch over must achieve a bump-less switch over.

4. The main instruments on site

In order to meet the liquid level, temperature, pressure and data monitoring of the petrochemical storage tank field, and in order to meet the entire production process and safety control functions of the petrochemical storage and transportation system, the field core instrument includes the liquid level, temperature, Pressure, control valves, transfer pumps and other equipments.

Liquid level gauge

The liquid level metering system is an important part of the petrochemical storage SCADA system. Generally, other level gauges such as radar or servo are installed in the tank. The metering accuracy of the level gauge is based on actual demand, with multi-point thermometer, pressure transformer, etc.. The single point current signal mode or serial communication mode is generally used between the liquid level meter and the system.

The standard system structure

(1) The level gauge mainly uses radar and servo level gauges, etc.

Remote monitoring of tank level measurement

| The optional brands are as follow |  |

| Selection according to different media and tank forms | |

| Precision is optional upon request | |

| Communication method is optional according to system requirements | |

| EMERSON/ENRAF/E+H/SIEMENS/KORHNE |

(2)Temperature measuring instrument

Detect the temperature of the tank or pipeline to achieve remote monitoring

| Option of domestic and imported products |  |

| Option of thermal resistance and thermocouple | |

| Option of integrated and split type | |

| Output signal is RTD, mV or 4-20mA |

(3)Level switch

Detecting the high and low positions of the tank level to achieve safety interlocking and remote monitoring

| The function is mainly the safety interlock of liquid level |  |

| Switch signal output | |

| Insert depth according to requirements | |

| Installation method of thread and flange |

(4) Pressure transmitter

Detecting the pressure of the tank or pipeline to achieve remote monitoring

| Output signal: 4~20 4-20mA with hart |  |

Accuracy: 0.075% | |

| Brand: Rosemount /YOKOGAWA/Chuanyi |

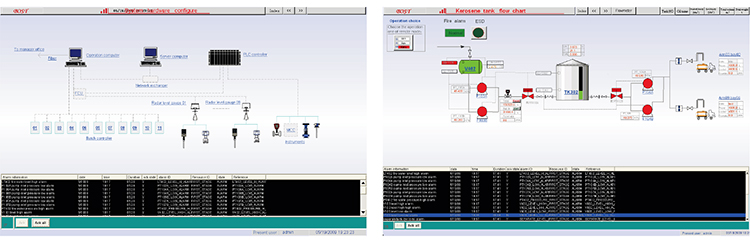

(5) Emergency shut-off valve SCADA System software screen

In order to meet the function of safety interlocking, the liquid hazardous chemicals

storage area is generally equipped with an emergency shut-off valve at key parts.

The emergency shut-off valve is generally pneumatic or electric (fireproof)

| Valve type optional butterfly valve and ball valve, gate valve (fireproof type) |  |

| Actuator optional pneumatic or electric | |

| Brand: domestic and foreign brands are optional |

(6)Control system cabinet

Protective cabinets for control and communication control functions, indoor or outdoor

Control cabinet is divided into system controller cabinet, communication cabinet and power cabinet |  |

| Standard size or custom type | |

| Flexible configuration according to function |

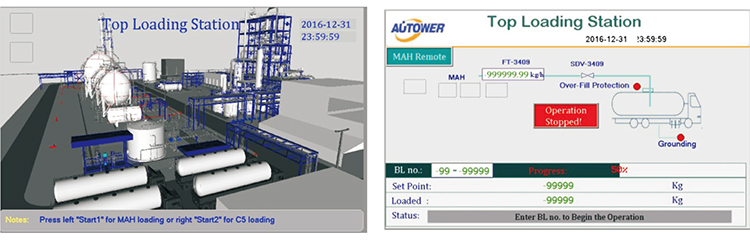

(7) Batch Controller

Remote monitoring of instruments for the control of incoming and outgoing batch

processes in the storage tank area

| Independent brand Autower (AWZ) |  |

| Select single loading position and multiple loading controller according to function | |

Select network communication method according to the overall network structure |

(8) Flow control instrument

Detect the flow of the main pipeline to achieve remote monitoring

| Select flow meter type based on media |  |

| Choose the appropriate caliber according to the flow range | |

| Brand: E+H, EMERSON, etc. |

Technical Parameters

| Condition | New |

| Dimension(L*W*H) | 4000x1500x1400mm |

| Medium | Water, Gas, Oil, LNG, LPG |

| Application | Liquid with Suspended Solids |

| Capacity | customized |

| Weight | 2.5~3 Ton |

| Usage | store and transport oil, beverage, medicine, chemical, etc. |

| Material | 20# steel, 304, 316, stainless steel |

| Function | store and convey products,widely used |

| Process Fluid | LOX/LIN/LAR / Expand Perlite Gas Storage Tank |

EN

EN

RU

RU