- Inquiry

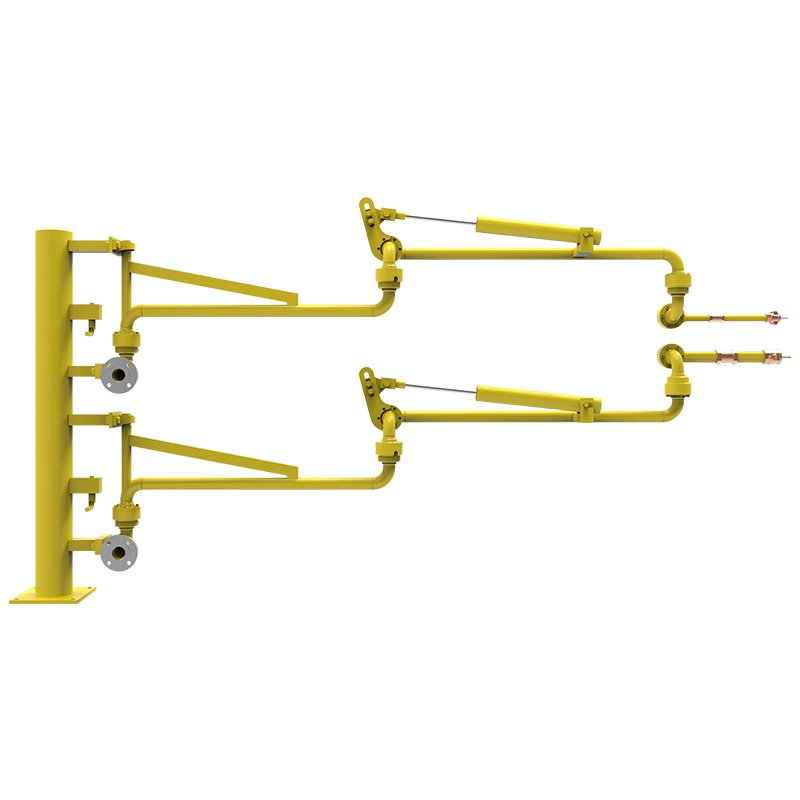

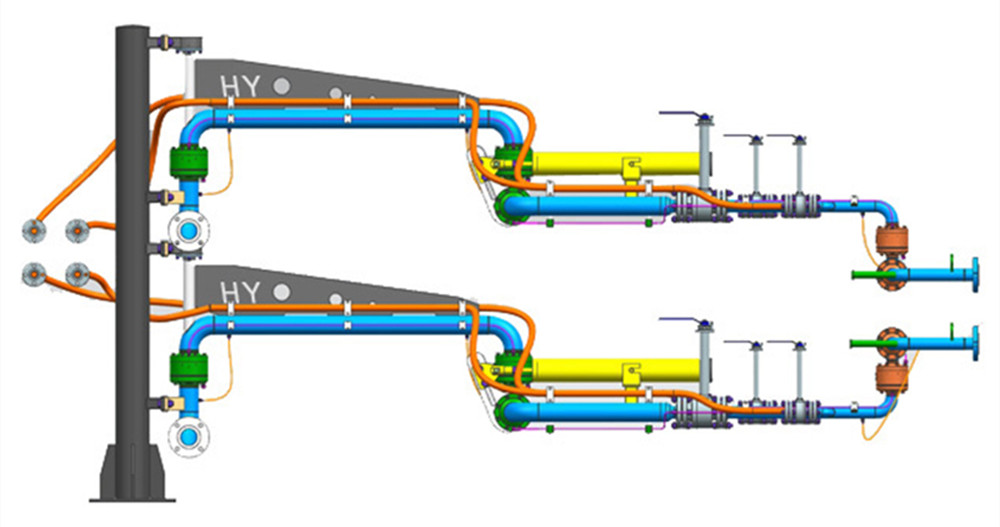

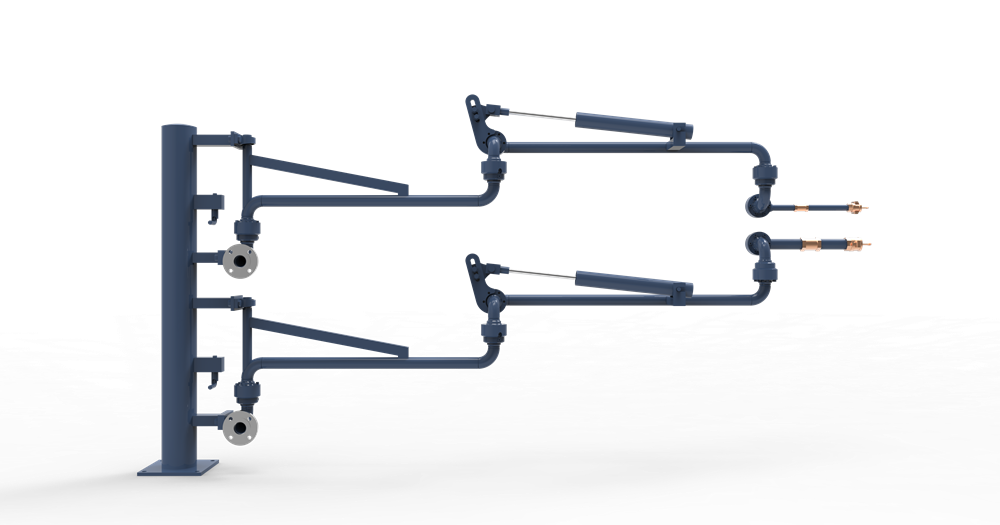

The loading arm (land fluid loading arm) is connected with pipes and elbows by means of a rotary joint.Special equipment for the transfer of liquid or gaseous products between loading platforms and road/railway tankers,Used to replace old-fashioned hose filling, with high safety, flexibility and economy.

Product performance

◆ The key piece rotary joint is made of alloy steel and stainless steel.Processed with precision CNC machine tools,Built-in double raceway support structure, able to withstand the harsh axial, radial and moment loads, flexible, reliable and leak-free.

◆ The sealing ring has a unique structure, adopts PTFE reinforced polytetrafluoroethylene material, embedded stainless steel skeleton, and the sealing surface is polished. The wear resistance is excellent, and the sealing performance is superior and reliable.

◆ The spring-cylinder balance system can be balanced at any point, making the alignment operation light and reasonable.

◆ All pressure main pipe welds are argon-arc welded and fully comply with HG/T 21608-96.

◆ Equipped with high-quality and reasonable electrostatic grounding system, the electrostatic resistance is less than 2Ω, and the safety performance is reliable.

◆ The structure is reasonable, with the smallest arm size to achieve the maximum envelope range.

◆ In the loading and unloading operation, the tank truck moves within the normal range and exhibits sufficient flexibility.

◆ The pipe material can be selected from carbon steel, stainless steel, low temperature steel, aluminum, glass reinforced plastic, and lining PTFE.

◆ The surface of the loading arm is sandblasted and rust-removed, using high-quality paint and advanced spraying technology.It not only guarantees good appearance quality, but also has strong corrosion resistance.

◆It is designed according to the left or right type design, and the structural form can also be specially designed.

◆ It can be configured with a reliable hydraulic, pneumatic or electric operating system and a secure alarm system.

◆ It can realize automatic operation, PLC control, convenient operation and maintenance.

◆ Smart and versatile accessories for environmental protection and safe operation.

◆ The loading arm is strictly tested and tested according to the HG/T21608 standard, and its performance parameters can be effectively guaranteed.

◆ Our company not only has the qualification of pressure piping design and installation, but also strictly implements the ISO9001 quality system.Control the entire process of the design, manufacture, installation and service of the loading arm.

Standards and specifications for the implementation/reference of loading arm

◆ HG / T21608-96 "Liquid loading arm"

◆ GB/74-84 "Code for Design of Petroleum Reservoirs"

◆GB50160-92 "Design rules for fire protection in petrochemical enterprises"

◆ GB383601 "General requirements for explosion-proof electrical equipment for explosive atmospheres"

◆GB7932 "General technical conditions for pneumatic systems"

◆ GB3766 "General technical conditions for hydraulic systems"

◆ GB150 "Steel Pressure Vessel"

◆ GB3323-87 "Steel fusion welded joint radiography and descaling grade"

◆ GB/T8932-88 "Corrosion grade and descaling grade of steel surface before painting"

◆ GB/T13384-92 "General technical requirements for mechanical and electrical product packaging"

Technical Parameters

| Applicable | This type of loading arm is used for loading and unloading of automotive liquefied gas or liquid ammonia products. |

| Medium | Liquefied petroleum gas, liquid ammonia, dimethyl ether and other highly volatile chemical media |

| Working pressure | 1.0MPa 、1.6MPa 、2.5MPa etc |

| Operating temperature | -196℃~+160℃ |

| Equipment Specifications | Liquid pipe nominal diameter range is DN50-DN200 |

| Optional accessories | Overfill grounding protector, liquid level switch, quantitative loading control system (flow meter, valve, pressure gauge, temperature and pressure transmitter), etc. |

EN

EN

RU

RU