- Inquiry

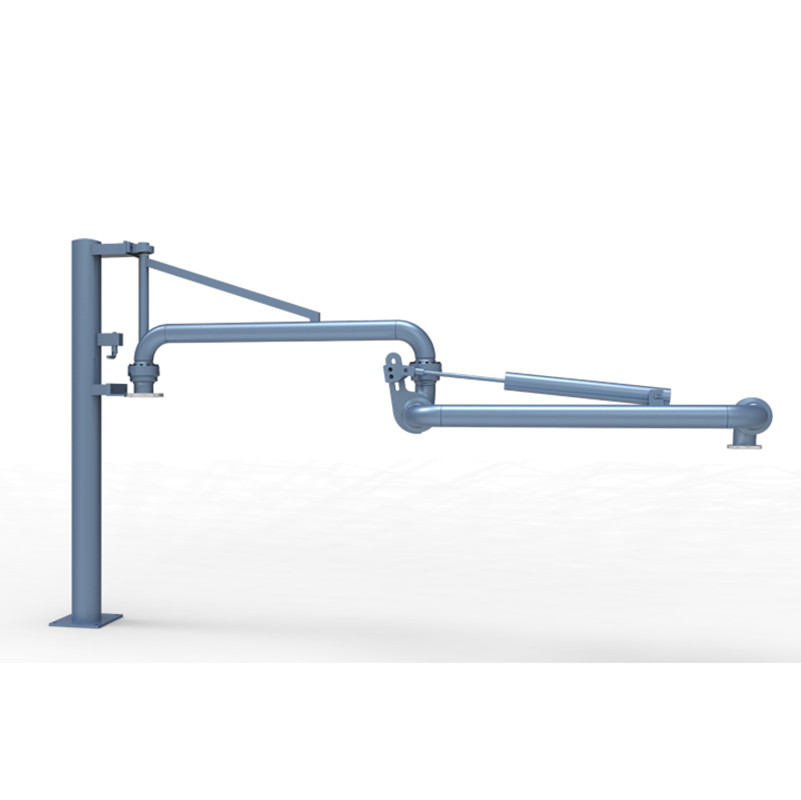

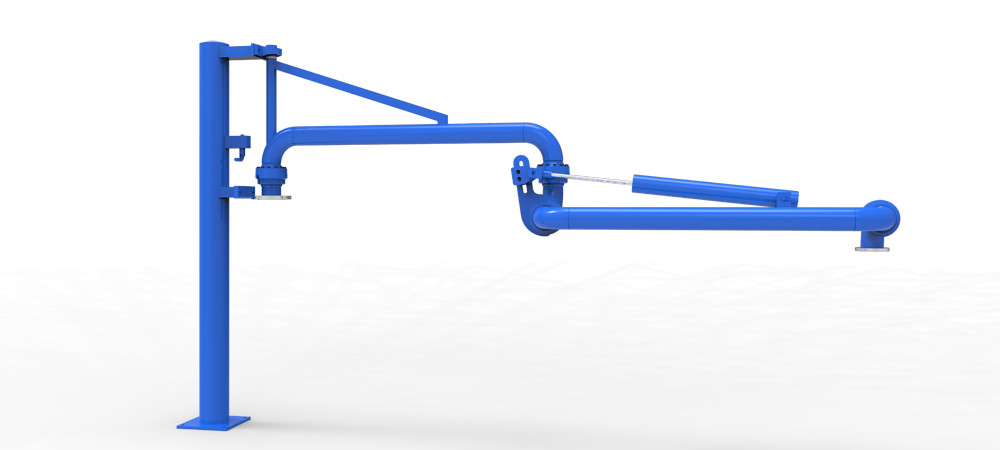

Overview of the Loading arm:

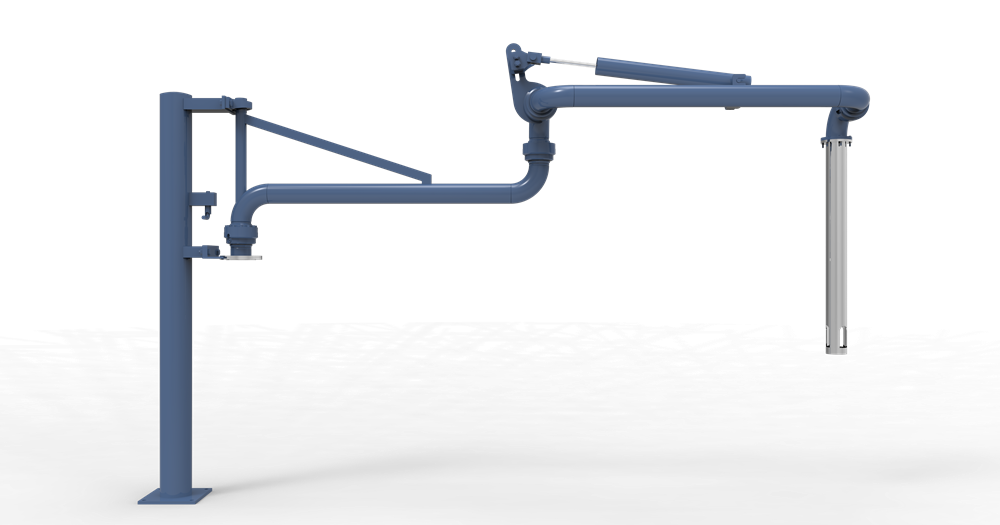

loading arm is a special equipment in the fluid handling process of the petrochemical industry, also called fluid loading arm.It uses a rotary joint to connect with steel pipes and elbows.It is convenient to realize the movable equipment for transferring liquid medium between the train, the car tanker and the trestle storage and transportation pipeline.Replacing old-fashioned hose connections for high safety, flexibility and long life. The product complies with the GB 50074-2002 "Petroleum Library Design Specification" standard.It is an ideal special equipment for the process of sending and receiving oil. It can also be widely used in the chemical industry and other industries to send and receive various liquid raw materials.

The loading arm is divided into a truck loading arm, train loading arm, airplane loading arm, and barrel loading arm.etc,From the loading type, it can be divided into Top loading and Bottom loading.The transportable medium includes petroleum products such as crude oil, gasoline, diesel oil and lubricating oil,It can also transport concentrated sulfuric acid, liquefied natural gas, liquefied petroleum gas, molten sulfur, asphalt, carbon disulfide and other chemical products.

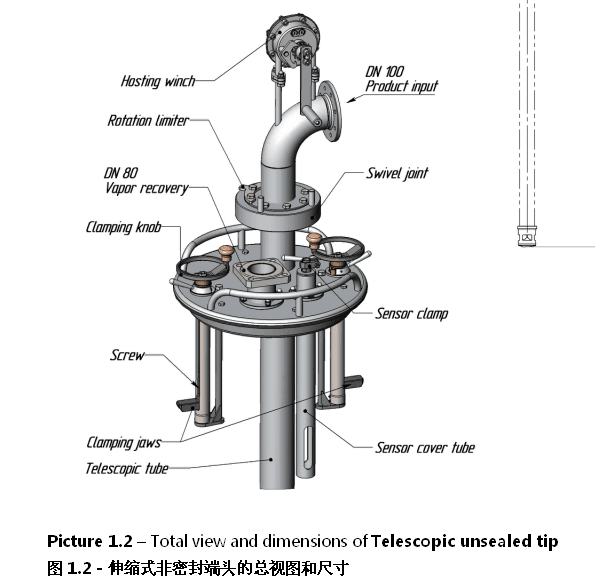

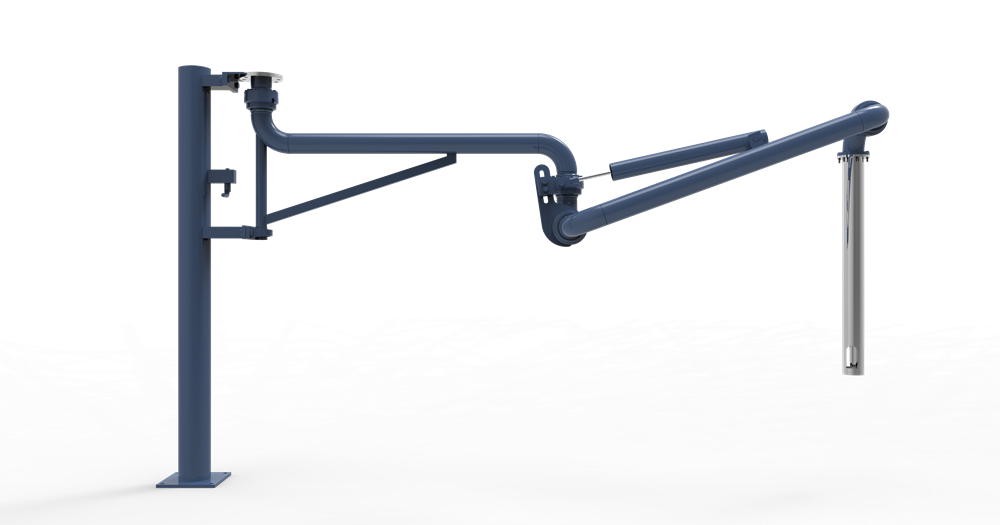

The loading arm is mainly composed of fixed, rotating, operating, balancing and other mechanisms and oil pipes.The slewing mechanism (slewing joint) is made of forged steel or aluminum alloy.Built-in double-row ball bearing, stainless steel special sealing ring, it has flexible rotation, reliable sealing performance and durability.The balance system has counterweights, torsion springs, compression springs, tension springs and lead screws, as well as hydraulic and pneumatic balances.All can be operated with a small force.It is a device that is connected to the pipeline by a rotary joint with a flexible rotation and good sealing, and is used for the liquid medium transfer operation between the tank truck and the trestle storage and transportation pipeline.

The mediums for AL1401/1402 are: crude oil, heavy oil, residual oil, tar, asphalt, liquid alkali, sulfuric acid, etc.Different materials and accessory parts can be selected as needed (such as heat pipe, electric heating, sealing cap, electrostatic grounding, liquid level oil, etc.)

Selection elements of AL1401/1402 loading arm

AL1401/02 Loading arm selection, 1401 loading arm and 1402 loading arm structure are basically similar, the difference is that the 1401 entrance is up, and the 1402 entrance is facing down.Mainly for the convenience of taking over, the pipe coming from the pipe gallery is generally upwards, which is convenient for the interface.The pipe coming from the trench,The entrance is facing down for easy interface.(In order to facilitate the uniform description of 1402, the 1401 function is the same as 1402, because most sites will adopt 1402)

The selection of the AL1401/1402 Loading arm generally has several major elements:1, loading tank trucks and trains2, the medium is liquid at normal temperature and pressure and is not flammable, explosive, volatile, toxic.If you meet the above two conditions, you can use 1401/02.Then select the detailed product parameters according to the parameters provided by the customer (see the parameter table for details).1. According to the flow selection caliber, the general DN50 loading capacity is 20--30 cubic meters per hour.DN80 is 50--70 cubic meters per hour.DN100 is 90--110 cubic meters per hour (flow rate is 3--4 meters per second) 2.According to the chemical properties of the medium, the pipe material is selected.Corrosive stainless steel is generally used (the specific material is based on physical properties)3.Select pipe wall thickness and flange rating based on operating pressure (typically PN16/PN25)

Technical Parameters

| Material | Crude oil, refined oil, chemical media |

| Work pressure | 1.0MPa、1.6MPa、2.5MPa etc |

| Operating temperature | -196℃~+160℃ |

| Equipment Specifications | Liquid pipe nominal diameter range is DN50-DN200 |

| Optional accessory | Overfill grounding protector, liquid level switch, quantitative loading control system (including filter, flow meter, valve, pressure gauge, temperature and pressure transmitter), etc. |

EN

EN

RU

RU