- Inquiry

LNG low temperature loading arm performance

LNG loading arm and low temperature loading arm (low temperature loading arm) should be applicable to low temperature operating conditions, long service life, safety and reliability.

LNG loading arm and low temperature loading arm (low temperature loading arm) should ensure the connection between the loading platform and the tank truck.Meet the requirements of fluid circulation. The convenience of replacing the rotary joint seal should be considered in the overall design or component selection design.At the same time, in order to ensure the safety of work, it is necessary to prevent sparks from being generated by static electricity, friction or collision.

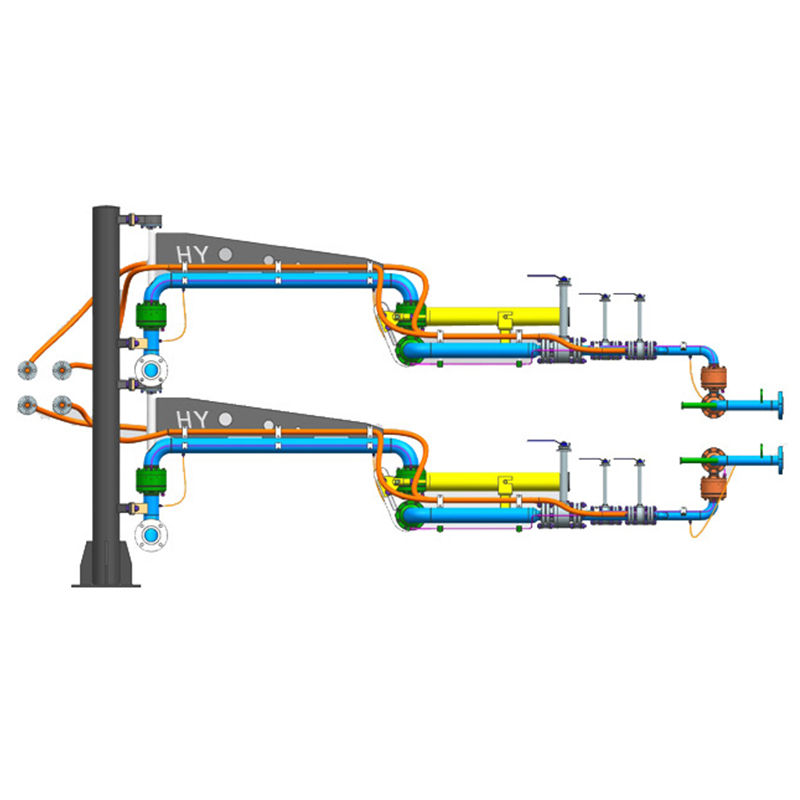

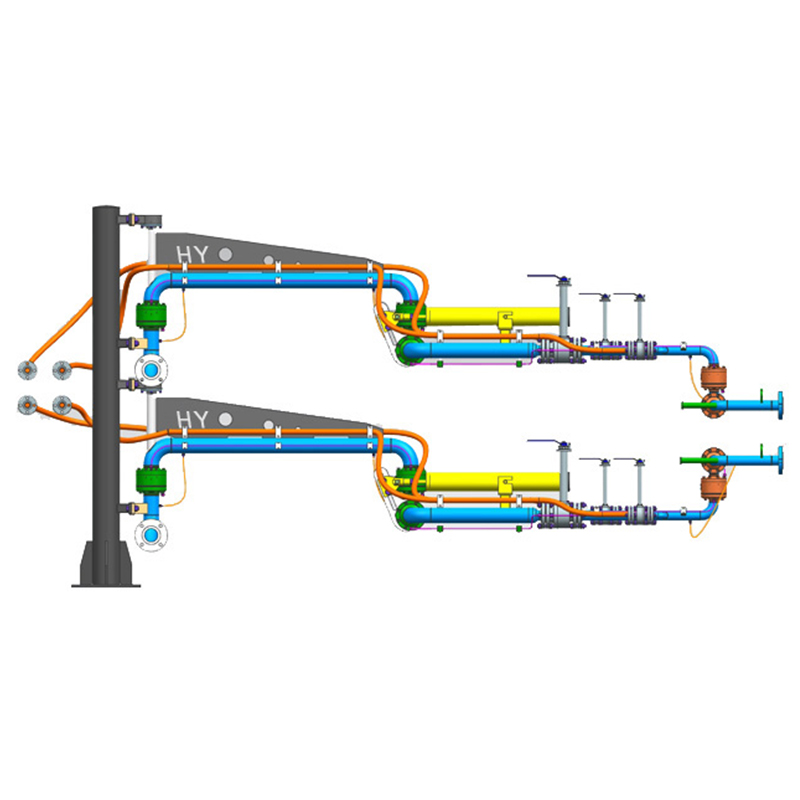

LNG loading arm (low temperature crane pipe) structure:

The LNG loading arm and the low temperature loading arm are composed of a column, a liquid phase arm, a gas recovery arm, a balancing device, a nitrogen purging device, an electrostatic conducting device, a rotary joint, and an emergency shut-off valve.

LNG loading arm, the lower end of the column is equipped with a connecting bottom plate, and is fixed on the loading platform by four bolts.

LNG loading arm and rotary joints require reliable sealing, flexible rotation and high strength, and long service life.The replacement method of the sealing ring is simple and convenient.The raw materials for the manufacture of low temperature loading arms must have a certificate of quality.

![]()

LNG crane pipe (low temperature loading arm) process:

1.The inner and outer ring compound raceway is finished by a precision CNC lathe at one time to ensure dimensional accuracy.

2.Inner ring stainless steel sealing surface mirror polished

3.The outer ring is tempered by T235

4.The sealing surface (metal sealing surface and sealing ring sealing surface) is mirror polished

5.Strict inspection of each process

6.All process pipelines of LNG loading arm (low temperature loading arm) are welded by TIG tungsten argon arc welding, and the weld is inspected by flaw detection to meet the requirements of Grade II or above.

Technical Parameters

LNG low temperature loading arm can be used for low temperature operation conditions, long service life, safe and reliable.

EN

EN

RU

RU