loading arm rotary joint

Characteristics

The dryer is for application in gelatin drying, which can also be used for dry granular, chip materials. It is equipped with lithium-chloride dehumidifier to control humidity required with varying air inlet regardless of weather helping to produce better quality product in an almost germfree ultra clean environment. It is low energy consumption, high efficient drying process, automatic continuous operating, simple operation and easy maintenance.

| Capacity: | Gelatin 500~4000T/Y |

| Control Mode: | Automatic control |

- Inquiry

Rotary joints for loading arm are generally used for the transport of liquid products in trestles and car tankers or train tankers.

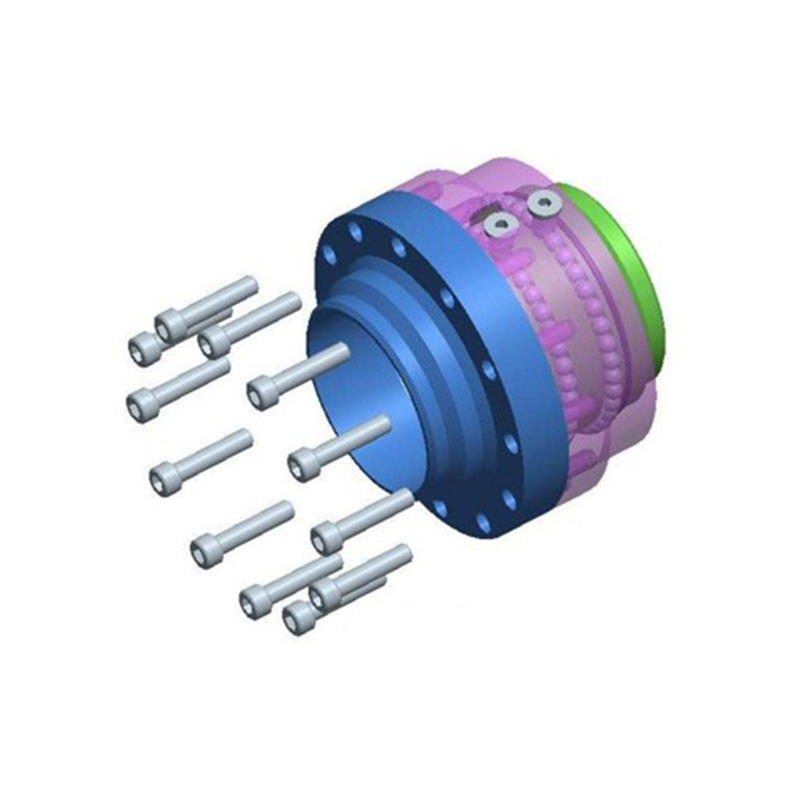

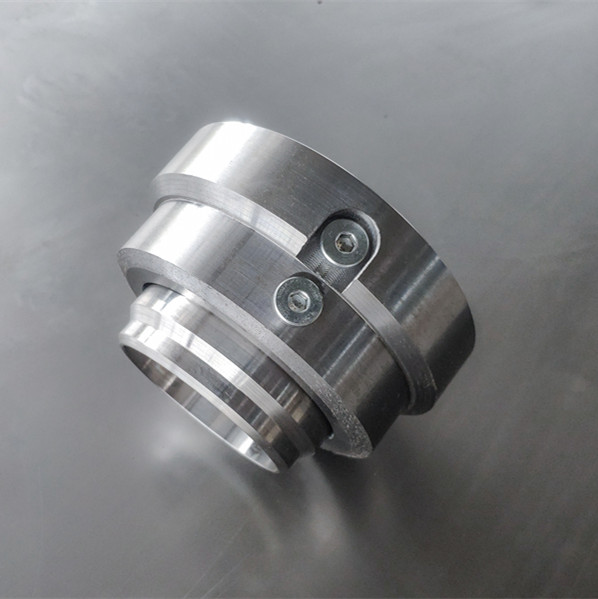

Loading arm rotary joint picture

Structure description

It is divided into open loading and unloading at the top of the tank truck, closed loading and unloading at the top of the tank truck, and loading and unloading at the bottom of the tank truck.There are two ways of balance weight and spring balance.The pipeline materials used include carbon steel, stainless steel, carbon steel and PTFE lining. And nitrile rubber, fluororubber, and polytetrafluoroethylene are used as sealing materials.

Standard design specifications for loading arm joints are DN50, DN80, DN100, DN125, DN150,Other specifications can be designed and manufactured according to customer needs.Its design pressure is PN0.6~PN6.0MPa, and the design temperature is -196°C~200°C.Automatic vacuum release valve, manual vacuum release valve, external arm lock, internal arm reset lock, oil tank, shut-off valve, liquid level alarm system and heat tracing system are also available as accessories.There are two kinds of manual and pneumatic driving methods, and the rotary joint is made of stainless steel for sealing surface.

Applicable medium

The swivel joint is a key component of the loading arm (fluid loading unloading arm).It is machined by precision CNC machine tools and has a built-in double raceway support structure.Flexible, lightweight and reliable. The outer ring is made of alloy steel, the inner ring is made of stainless steel or PTFE-lined to ensure that it can be safely and reliably used for high temperature, low temperature and strong corrosive media.

Reinforced PTFE as a sealing ring material, and lined with stainless steel elastic support ring, the seal is polished, and has excellent self-lubricating corrosion resistance.

Product attribute

| Material | Carbon steel, stainless steel, carbon steel PTFE lining |

| Work pressure | PN0.6~PN6.0MPa |

| Operating temperature | -196℃~200℃ |

| Equipment Specifications | DN50、DN80、DN100、DN125、DN150 |

| Optional accessory | Automatic vacuum release valve, manual vacuum release valve, external arm lock, internal arm reset lock, oil tank, globe valve, liquid level alarm system, heat tracing system |

Technical Parameters

| Model | WX-4501 |

|---|---|

| Packaging film thickness | 18-60Mircon |

| Max. film width | 420mm |

| Bag length | 150-600mm |

| Packaging width | 50-180mm |

| Packaging height | 30-70mm |

| Packing speed(Depend on packing material) | 8-28bag/min |

| Machine dimension | 2300×1000×2150mm |

| Machine weight | 600kg |

EN

EN

RU

RU