- Inquiry

The main purpose and application scope

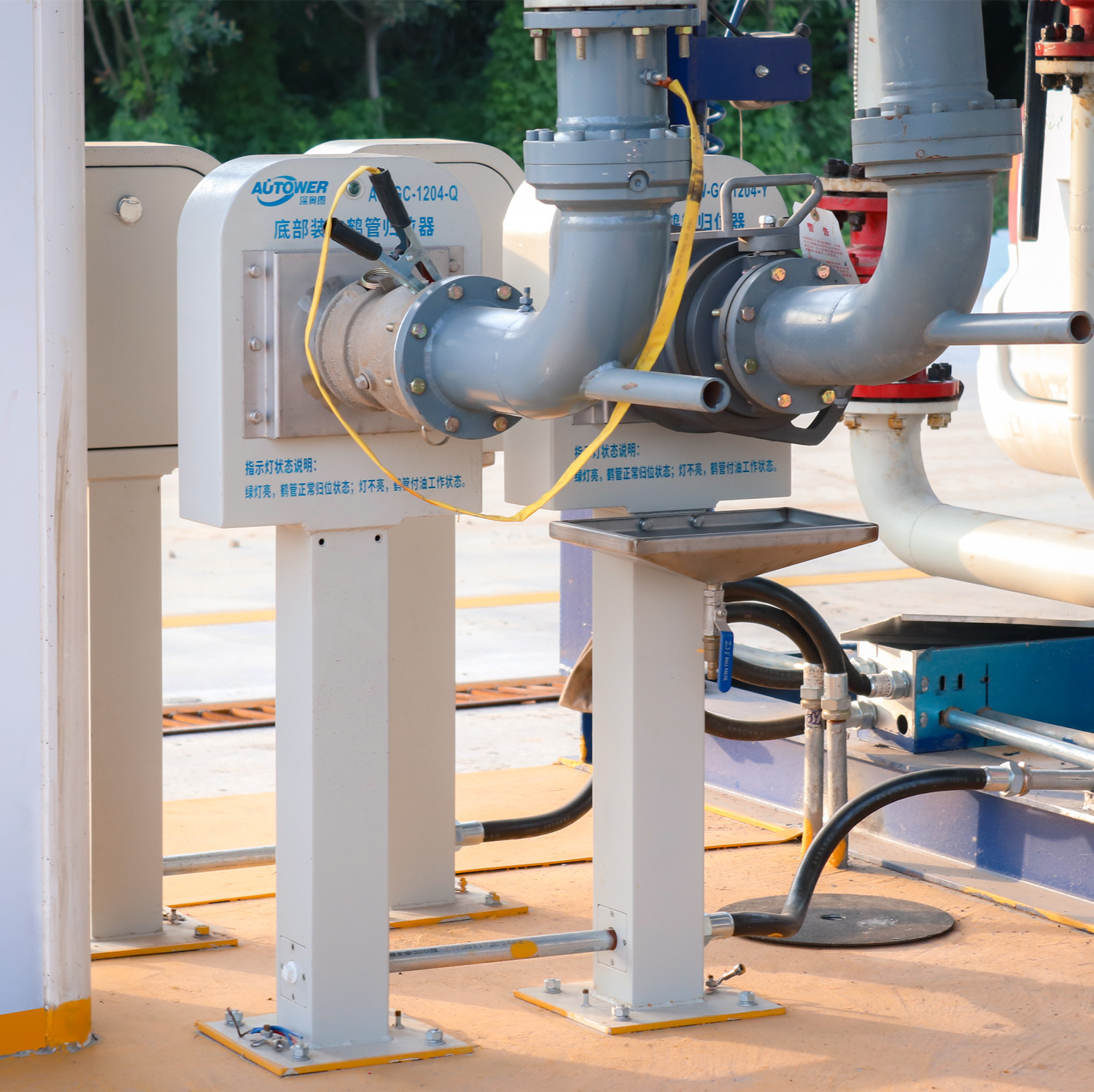

Applicable to this equipment is only applicable to the liquid canning process of oil depots and chemical production units. In the face of dangerous locations and dangerous liquids, this equipment complies with API standards for tank trucks (with oil spill probes and API joint seats). It is specifically designed for the normal and reliable return of cranes after the loading and unloading operations of petrochemical products are completed. Designed. It is mainly applicable to flammable and explosive oil depots and oil stations. It can also be applied to canned systems of liquid benzene, hydrocarbon sealed loading vehicles and other corrosive chemical products.

Using environmental conditions

The AW-DLH-24 bottom loading arm retractor should work normally under the following environmental conditions:

Ambient temperature: 5 °C ~ +35 °C

Average relative humidity: ≤ 95% (+25°C)

Atmospheric pressure: (80 ~ 106) KPa

Oil depots and chemical production are equipped with gasoline, diesel, methane, liquid benzene, hydrocarbons and other explosive mixture handling and production sites

Environmental noise: no more than 75dB

Others meet the requirements of their respective product standards

Each product in the AW-DLH-24 type bottom loading crane can withstand the worst storage and transportation conditions:

Low temperature: -40°C

High temperature: +60°C

Average relative humidity: ≤ 95% (+25°C)

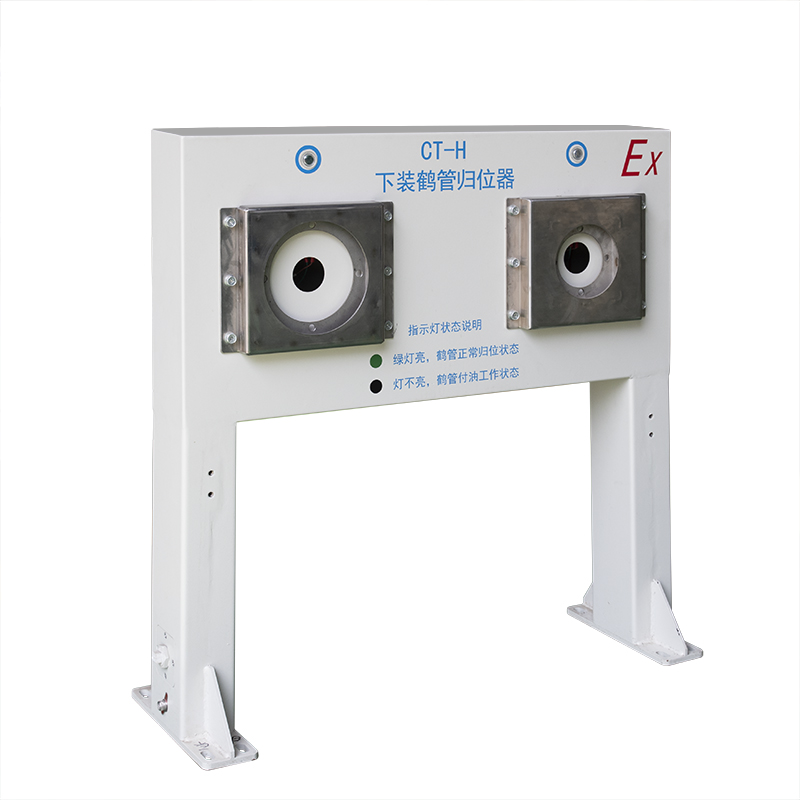

Model meaning and composition

| AW | Manufacturer code |

| DLH | Bottom liquid loading arm |

| 24 | Operating voltage |

Technical Parameters

| Input voltage | 24VDC |

| Response time | <1S |

| Working current | <20mA |

| Explosion-proof grade | Exdia ⅡBT6 Gb |

| Alarm method | Light alarm |

| Input and output signal | Switch quantity dry contact |

| Operating temperature | -40℃~60℃ |

| Unit size | 300*200*855mm |

EN

EN

RU

RU