- Inquiry

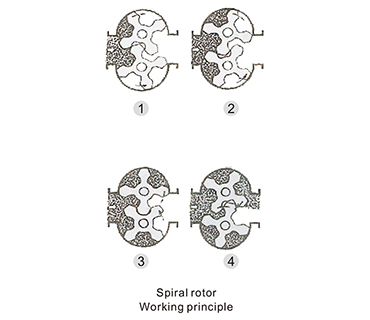

Working principle

The flowmeter is a volumetric flowmeter, which is composed of a helical rotor (measuring component) and an inner wall of a flow box to form a closed cavity (shaded in the figure) as a measuring chamber, and the rotor can output 8 times per revolution. The volume of the cavity. Therefore, the number of revolutions of the spiral rotor is proportional to the cumulative flow rate of the fluid.

Application field

A dual-rotor flowmeter (hereinafter referred to as a flowmeter) is a precision instrument for measuring and controlling the flow of liquid in a tunnel. The flowmeter can be made of different materials and is widely used in petroleum, chemical, light industry, commercial and scientific research departments. It is especially suitable for the measurement of industrial liquids such as crude oil, refined oil, alcohols and light hydrocarbons. Flow meter. The flow meter has a field indication, the word code direct reading field indication count can be returned to zero. The electric pulse signal can be output for display instrument and computer processing, thereby realizing centralized control of management flow over long distances

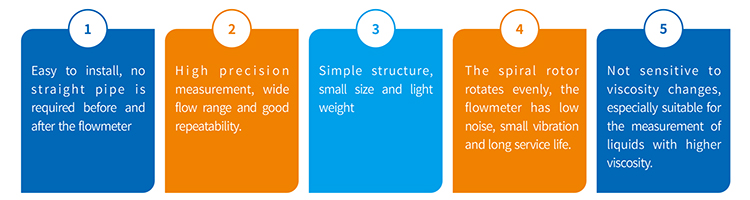

Main feature

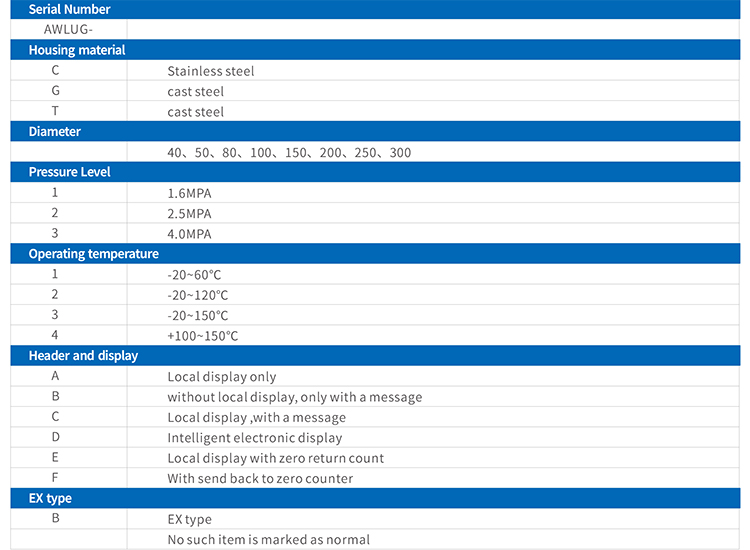

Double rotor flowmeter selection

Technical Parameters

| Nominal diameter(mm) | 40、50、80、100、150、200、250、300 |

| Allow basic error(%) | ±0.2、±03、±0.5 |

Repeatability error(%) | 007(0.2%、0.3%)、0.17(0.5%) |

| Allow work pressure(Mpa) | 1.6、2.5、4.0、6.4 |

| Medium temperature(℃) | -20~+60℃、-20~+120℃、-20~+150℃、-20~+200℃ |

| Medium viscosity(Mpa·s) | 0.6--200 |

| Explosion-proof grade | EXdIIB T6(Note: The signal remote transmission flowmeter is divided into normal type and explosion-proof type.) |

| Pipe flange standard | JB79-59 JB82-59 GB9122-1988 GB9113-1988 |

| Main material | Stainless steel, stainless steel, cast iron |

EN

EN

RU

RU