- Inquiry

Product description

High reliability

The AWZ series loading instrument adopts industrial grade products with mature technology and reliable performance. Its core controller adopts a programmable controller commonly used in the industry. The LCD display and keyboard input part adopts imported integrated LCD operation terminal, and the upper computer monitoring software adopts The mature industrial control configuration software makes this product have an absolute advantage unmatched by single-chip products in terms of advancement and reliability.

Multiple safety design

The grounding signal is automatically detected before and during the loading process, and the loading operation is prohibited if there is no safety grounding.

Multi-level operation authority is set, and parameter setting or operation can be performed only when the operation authority is satisfied.

With equipment self-diagnosis and alarm functions.

Flexible networking capabilities

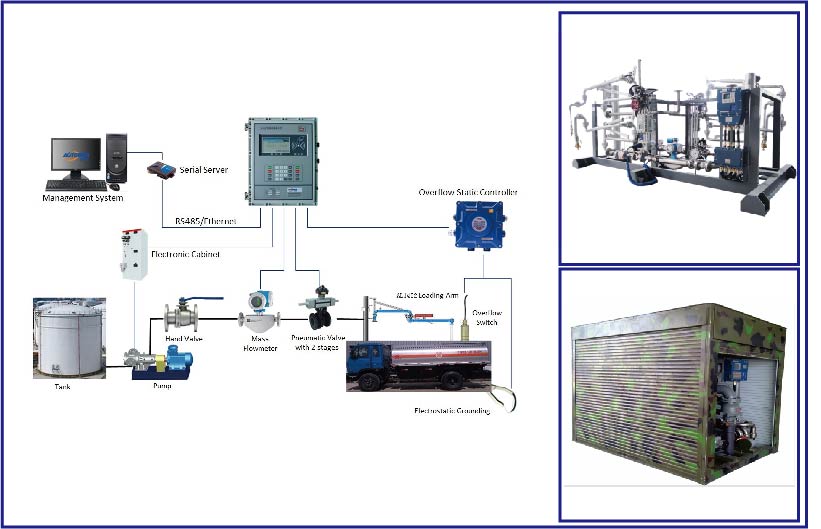

The AWZ series loading instrument provides two communication options: Ethernet and RS485 network.

When using Ethernet, the communication protocol is the open Modbus TCP/IP protocol commonly used in process control, and the network communication rate is as high as 10Mbps, which is much higher than the ordinary RS485 network (600~115200 bps).

When using Ethernet, the communication protocol is the open Modbus TCP/IP protocol commonly used in process control, and the network communication rate is as high as 10Mbps, which is much higher than the ordinary RS485 network (600~115200 bps).

Flexible configuration

According to the buyer's needs, this series of loading devices can provide multiple options such as one machine (one loading device controls one loading arm position) and one machine with multiple positions (one loading device controls two or more loading arm positions).

Easy to maintain and use

System hardware adopts modular design, each module is easy to install and easy to maintain; software adopts graphical interface, easy to operate.

Remote and local operation modes

This loading instrument provides two operation modes: remote operation and local operation. When the operation mode is set to remote, it is only allowed to modify the working parameters on the remote management computer for loading operations; when the operation mode is set to local, it is allowed to modify the working parameters on the local loading instrument for loading At the same time, the working parameters and equipment status are simultaneously displayed on the remote management computer.

The functions are as follows:

Parameter setting function

The batch controller can set the loading parameters through the remote monitoring computer or the batch controller according to the needs of loading. These parameters include: flow coefficient, advance, valve opening delay time, fluid density, etc.

Quantitative loading control

After determining the working parameters of the batch controller, the batch controller will complete the automatic loading process according to the specified procedure, and automatically stop loading when the loading volume reaches the set value.

Grounding protection function

When it is detected that the system is not safety grounded, stop loading the vehicle.

Power failure protection function

When an unexpected power failure occurs during the loading process, the loading parameters can be saved, and the loading can be continued after the power is turned on.

Data collection function

The batch controller can collect flowmeter pulse signals or standard current signals, and can access thermal resistance temperature signals through the transmitter, and can also access switching signals such as electrostatic grounding clamps.

Continuous valve control function

The batch controller has PID adjustment output function, which can linearly and continuously control the opening degree of the on-site regulating valve, realize the functions of two-stage or multi-stage switch, constant current speed regulation, etc., to provide control effect and accuracy.

On-site emergency stop function

Both the batch controller and the remote monitoring screen are equipped with emergency stop buttons. If an emergency occurs on site during loading, the operator only needs to press the emergency stop button to immediately stop loading.

Remote and local real-time monitoring function

The batch controller is equipped with a high-brightness LCD display, which can display the loading process and the status of related equipment in real time when operating on site. During remote operation, the remote monitoring computer and the loading instrument can display the loading process and the status of related equipment in real time.

Remote/on-site loading mode conversion function

Generally, the truck is remotely loaded through the upper computer under normal conditions, or it can be directly loaded on site as needed. Each loading instrument in this system is a complete metering, control and display unit, independent of the upper computer.

Power supply function for field instruments

This batch controller also provides power output terminals to provide 24VDC and 220VAC power for field instruments such as flow meters and valves.

Communication network function

This batch controller is an open system with powerful communication and networking capabilities, and can be connected to the host computer and other systems in the form of Ethernet or RS485 network.

Equipment self-check function

The system automatically detects the working status of the batch controller, and the monitoring computer can remotely monitor the working status of the batch controller. When the batch controller fails, the system will automatically alarm.

Operation authority setting

This loading instrument can be set with a three-level six-digit operation password, which can be operated only when the password level is correct.

On-site printing function

This system comes with the printing function of the cumulative loading volume for each loading

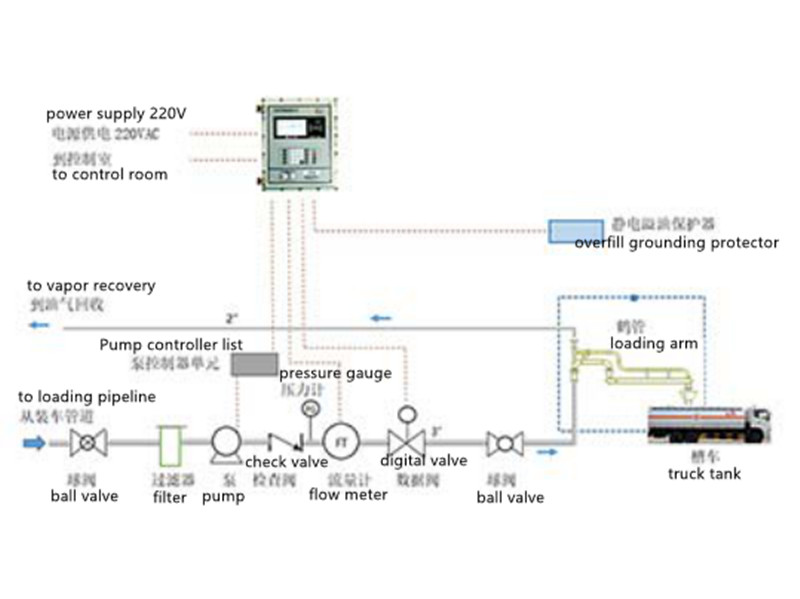

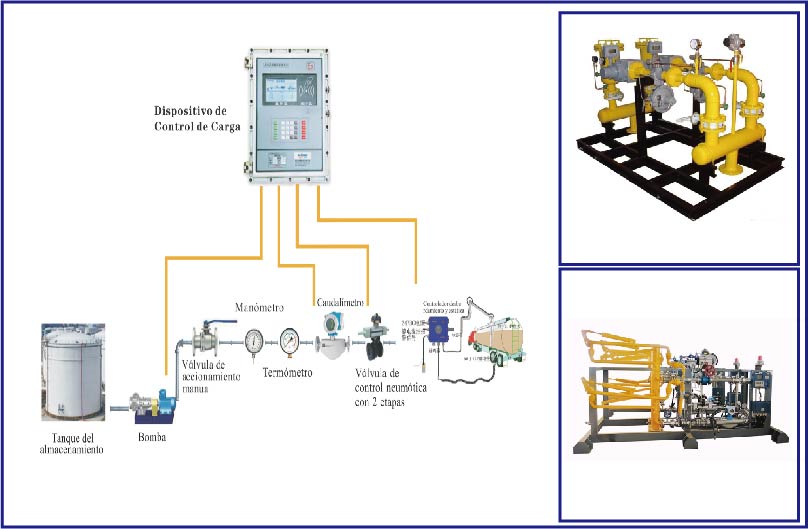

Top-mounted loading system configuration requirements and characteristics |

Quantitative loading controller: one machine per loading position |

Piston-type CNC electro-hydraulic valve: For non-corrosive, high-temperature and high-pressure media, you can choose a control valve made of carbon steel, 16MPa pressure, and normal temperature. The piston type numerical control electro-hydraulic valve has excellent constant current and multi-stage control functions. The linear control is excellent, the constant velocity response is adjustable, and the low pressure drop and the small flow rate can be stably controlled at one liter per second when the flow rate is high, which can realize the constant flow function. It can solve the overshoot problem and eliminate the water hammer phenomenon. And long life. The high precision of oil delivery. |

Flowmeter: No special requirements can choose the volume flowmeter or mass flowmeter made of ordinary carbon steel. If there are higher requirements for the loading accuracy, it is recommended to choose an imported mass flow meter with 0.1% accuracy. |

Electrostatic protector: The electrostatic grounding protector is a grounding device to ensure the safety of the loading process. It has the interlocking function of refusing to load the vehicle without grounding signal and emergency stop when the grounding resistance is greater than 100Ω. At the same time, the device itself has a sound and light alarm function, and on-site operators can troubleshoot the fault through the color, sound and status of the light. |

Overfill protector: overfill protection is a safety device to prevent materials from overflowing the tanker when an accident occurs during loading. When the material comes into contact with the anti-overflow probe, the device will send an interlock signal to emergency stop. At the same time, the device has a sound and light alarm function, and on-site operators can troubleshoot the fault through the color, sound and status of the light. |

loading arm: The top-loadingarm is made of carbon steel, 1.6MPa, and the normal temperature type, which is volatile to the top-loading medium. For environmental protection and resource waste, it is recommended to choose a sealed and compressed, with oil and gas recovery Functional AL1412 loading arm. |

Product feature

The hardware of the quantitative loading control instrument of this system is mainly composed of a micro PLC module, a liquid crystal operation panel (including operation keyboard) and other auxiliary equipment (terminals, power supply, explosion-proof box, etc.). Based on this hardware design and configuration, the whole device has many natural advantages with the traditional system consisting of single-chip integrated circuits.

Technical Parameters

Product parameter | One machine multiple |

Power supply | AC220V,2A,50Hz. |

LCD | High-brightness STN 7-inch color LCD module |

IC card reader | Non-contact real-time reading, the reading distance is less than 50CM, supports various radio frequency cards |

keyboard input | 24 intrinsically safe waterproof membrane buttons, Chinese menu operation |

Equipment self-check | Automatic detection of equipment working status and remote monitoring |

Flow signal | Can be connected to 4 groups of 0~10KHz pulse input |

Valve position signal | Up to 13 switch contact valve position signals can be connected |

Relay output | AC220V, 5A, can control 10 valves or pumps (more expandable) |

Analog input signal | Supports two 4~20mA current input signals (configured according to needs) |

Analog output signal | Can support a 4~20mA current output signal (configured according to needs) |

System accuracy | Accumulative flow error ± (0.1% FS) |

Temperature compensation accuracy | Better than 0.1% |

Operation mode | It can be operated continuously for 24 hours without interruption, and can be operated locally or remotely |

Operating temperature | -30ºC~70ºC |

Stored temperature | -40ºC~100ºC |

Relative humidity | 0-100% |

Vibration | 0.5mm displacement, 10-55Hz, 2 hours XYZ three directions. |

Setting range | 0~99999Kg/L |

Communication Interface | RS485,RJ45 |

Communication Protocol | Modbus RTU (serial port), TCP/IP protocol |

Communication rate | 600~115200 bps (serial port), 10~100M (Ethernet) |

Mean time between failures | MTBF >100,000hours(11 Years) |

Explosion-proof grade | ExdIIBT6 |

Installation | Wall-mounted |

Size | 400(L)x500(H)x200(D) |

Electrical Interface | G3/4"(12pcs) |

EN

EN

RU

RU