- Inquiry

Product description

The host computer system is used for the operation and monitoring of the technological process, the monitoring of equipment status, the monitoring and confirmation of equipment failures, graphical dynamic display, on-site detection point display, detection and alarm, process parameter setting, remote valve control , Process trend display and storage, faults and production report printing, etc.

The configuration software adopted by the operating station is the company independently developed AWZ-V-1.0. As an operating station, its main functions include:

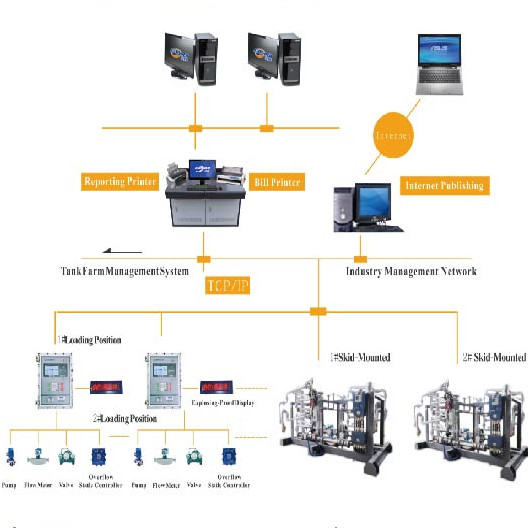

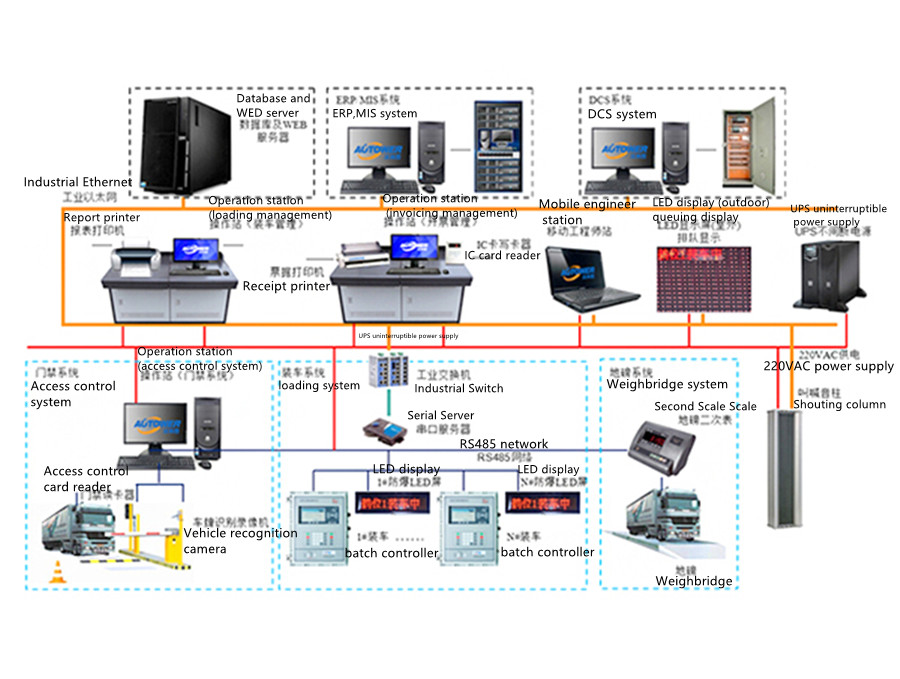

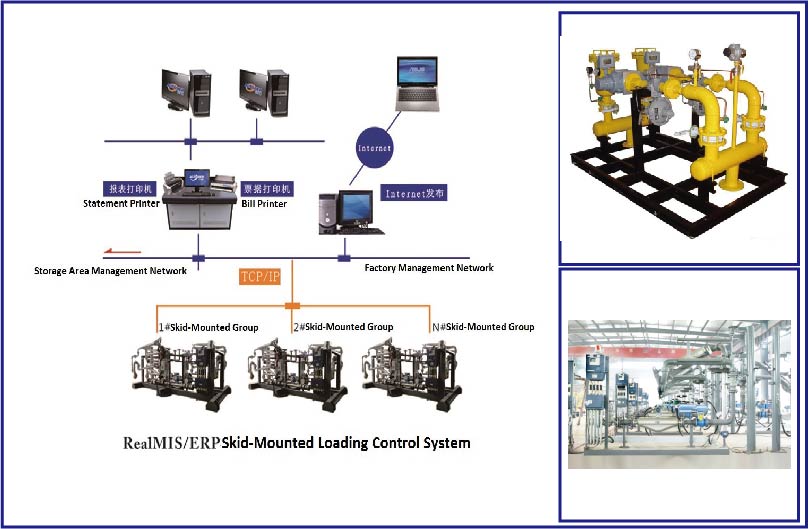

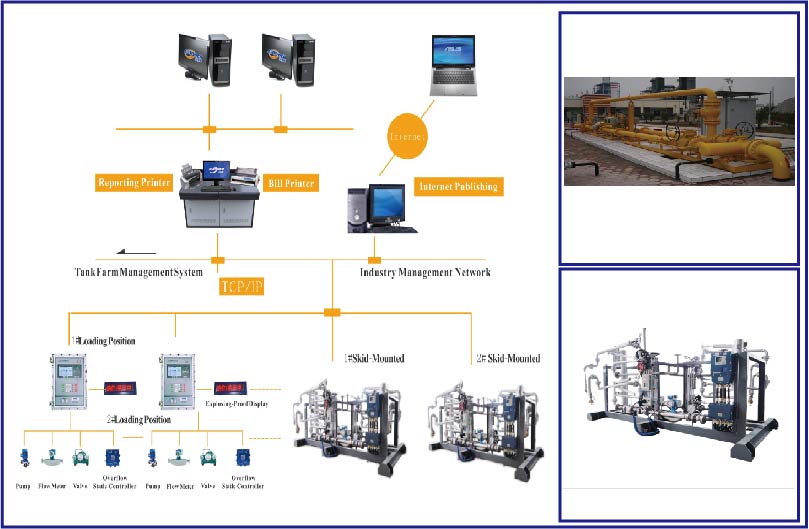

Host computer system structure

The structure of the host computer system is designed into the structure of BS. B/S structure (Browser/Server, browser/server model) is a network structure model after the rise of WEB. WEB browser is the main application software of the client. This mode unifies the client, concentrates the core part of the system's function realization on the server, and simplifies the development, maintenance and use of the system. Only one browser, such as Internet Explorer, needs to be installed on the client.

The server installs SQL Server database, and installs the developed software for data collection, storage, monitoring and management functions. The browser interacts with the database through the Web Server.Client users need to log in when using the management software. The management software can divide users. Different users have different permissions. The operation of the software is also related to permissions. For example, logging in to the loading monitoring management system can only Display screens related to loading monitoring and management. Operators can perform business-related operations on it. After the user of the access control system logs in, he can only browse one screen, that is, the comparison information after the driver has swiped his card. The information determines whether to release.

The software function design of the host computer system

The software development function is divided into blocks, each function block has an operating menu, each menu is layered, and each layer corresponds to a business process. The entire software interface is simple and user-friendly; each function block is set for different operating users. After logging in a user on the system, the inoperable functions are blocked according to the user's authority, the user cannot enter the function block for operation, the operable functions are displayed normally, and the user can enter the function block for business process operations.

The upper computer operating station mainly completes system management (operator login, operator management, vehicle management, loading oil management, database management, etc.), report statistics query (daily report, monthly report, classified query report), billing record management, Event record query, operation record query, online monitoring of loading process (loading overview map, loading arm position parameter setting, real-time alarm, loading record storage), single loading arm position loading control operation (invoicing, ticketing, suspension, Reset) etc.

Technical Parameters

Control the number of loading arm positions | One machine multiple |

Power supply | AC220V,2A,50Hz. |

LCD | High-brightness STN 7-inch color LCD module |

IC card reader | Non-contact real-time reading, the reading distance is less than 50CM, supports various radio frequency cards. |

Keyboard input | 24 intrinsically safe waterproof membrane buttons, Chinese menu operation |

Equipment self-check | Automatic detection of equipment working status and remote monitoring |

Flow signal | Can be connected to 4 groups of 0~10KHz pulse input |

Relay output | AC220V, 5A, can control 10 valves or pumps (more expandable) |

Analog input signal | Supports two 4~20mA current input signals (configured according to needs) |

Analog output signal | Can support a 4~20mA current output signal (configured according to needs) |

System accuracy | Accumulative flow error ± (0.1%FS) |

Temperature compensation accuracy | Better than 0.1% |

Operation mode | It can run continuously for 24 hours, and can be operated on site or remotely |

Operating temperature | -30ºC~70ºC |

Stored temperature | -40ºC~100ºC |

Relative humidity | 0-100% |

Vibration | 0.5mm displacement, 10-55Hz, 2 hours XYZ three directions. |

Setting rang | 0~99999Kg/L |

Communication Interface | RS485,RJ45 |

Communication Protocol | Modbus RTU (serial port), TCP/IP protocol |

Communication rate | 600~115200 bps (serial port), 10~100M (Ethernet) |

Mean time between failures | MTBF >100,000 hours(11Years) |

Explosion-proof grade | ExdIIBT6 |

Installation | Wall-mounted |

Size | 400(L)x500(H)x200(D) |

Electrical Interface | G3/4"(12pcs |

EN

EN

RU

RU