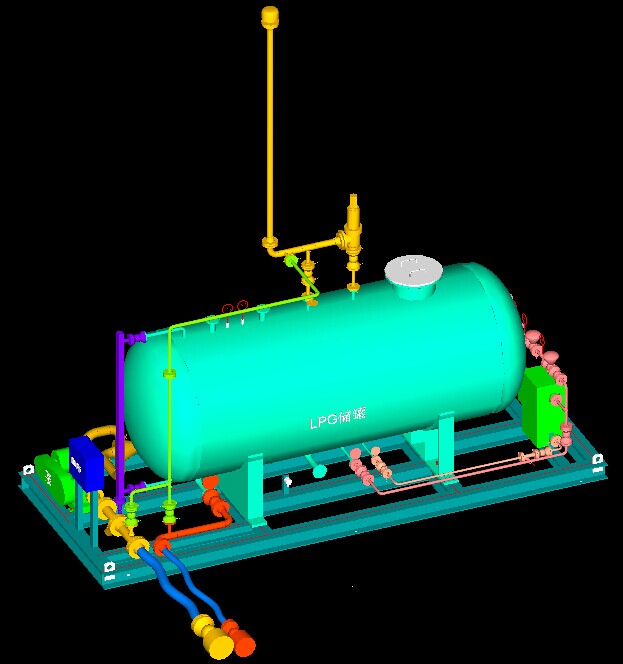

Pressure regulation and loading and unloading technology of LNG skid-mounted gas filling station

The pressure regulation technology of LNG skid-mounted refueling station can be divided into two types, one is self-increasing pressure regulation and the other is pump pressure regulation.

Self-increasing means that the LNG liquid in the station storage tank enters the vaporizer by the pressure difference caused by the water level, and returns to the top of the storage tank after being vaporized by air temperature, increasing the working pressure of the storage tank (this function can be used in the power failure It can be used under conditions to ensure that the car can be refilled even when the power is off). Using self-increasing means to increase the rate is slower than that, but it does not consume power.

The increase of the pump means that after the liquid in the storage tank flows into the pump pool (the pump pool needs to be quenched first), it is introduced into the vaporizer by the submersible pump, and then vaporized by air temperature, and then enters the top or bottom of the storage tank, which is used for lifting station storage Working pressure of the tank. This technique can also be used to adjust the saturation temperature of the storage tank.

The liquid filling technology of skid-mounted LNG filling station specifically involves the whole process of quenching, filling and dormancy.

The whole process of rapid cooling-with the help of the liquid level difference between the station storage tank and the pump pool, the liquid is allowed to enter the pump pool from the station storage tank to realize the rapid cooling of the pump pool. After the rapid cooling of the pump pool is achieved, the pump is turned on, and the refilling gun and the vending machine are inserted into the muzzle, and the refilling gun is connected to the vending plug muzzle, and then press the "Quick Cool" button on the control panel of the dispenser, LNG is circulated from the liquid phase of the storage tank, a pneumatic pump imported from the pump—pump, a check valve, a mass flow meter, a gas vending machine, a liquid phase pneumatic valve, a gas gun, a gas phase pneumatic valve, and a storage tank. When the temperature, density, and gain reach When the preset value is set, the rapid cooling of the dispenser is realized, and this whole process is also called large-cycle rapid cooling.

In the whole process of refilling, the truck can be refilled after the rapid cooling of the dispenser is achieved. Press and hold the "fill" button on the dispenser control panel to automatically refill the truck.

In the whole process of refilling, the truck can be refilled after the rapid cooling of the dispenser is achieved. Press and hold the "fill" button on the dispenser control panel to automatically refill the truck.

The whole process of dormancy-After the pump is turned on, when there is no signal from the dispenser for refilling and quenching, the pump runs at low speed, and the liquid circulates in the pipeline to maintain the temperature of the pipeline, reduce the number of pump start and stop times, and extend the working life of the pump. When there is no signal from the dispenser for a long time, the pump stops working.

EN

EN

RU

RU