Various processes and advantages and disadvantages of VOC waste gas treatment

VOC refers to organic substances that are relatively volatile.Because the components in general electronic equipment will use resin and glue, they also contain VOC.Moreover, when using electronic equipment, the temperature is relatively high. Some of the semi-volatile organic compounds SVOC that volatilize at room temperature will be volatilized at higher temperatures. Some VOCs with vaporization points above 40°C will have a rapid increase in radiation.Therefore, we generally use VOC waste gas treatment equipment. Here is a detailed introduction to the common processes for VOC waste gas treatment.

Various processes and advantages and disadvantages of VOC waste gas treatment

1. [Spray + Plasma] process

The core principle used is plasma field decomposition.

Advantages: The equipment has a small footprint, mainly for low concentrations.

Disadvantages: There are certain safety risks, and the purification effect is unstable.

2. [Spray + UV photolysis] process

The core principle adopted is ozone decomposition.

Advantages: high purification effect, stable treatment effect, mainly for low and medium concentrations.

Disadvantages: need to control the oxidation residence time.

3. [Spray + photolysis plasma] process

The core principle used is composite ozone and plasma.

Advantages: high purification efficiency, mainly for medium concentrations.

Disadvantages: There are certain safety risks.

4. [Microbiological Method] Process

The core principle adopted is biodegradation.

Advantages: no secondary pollution, low equipment energy consumption.

Disadvantages: high operation requirements, large equipment volume, need to replenish microorganisms regularly, and high maintenance costs.

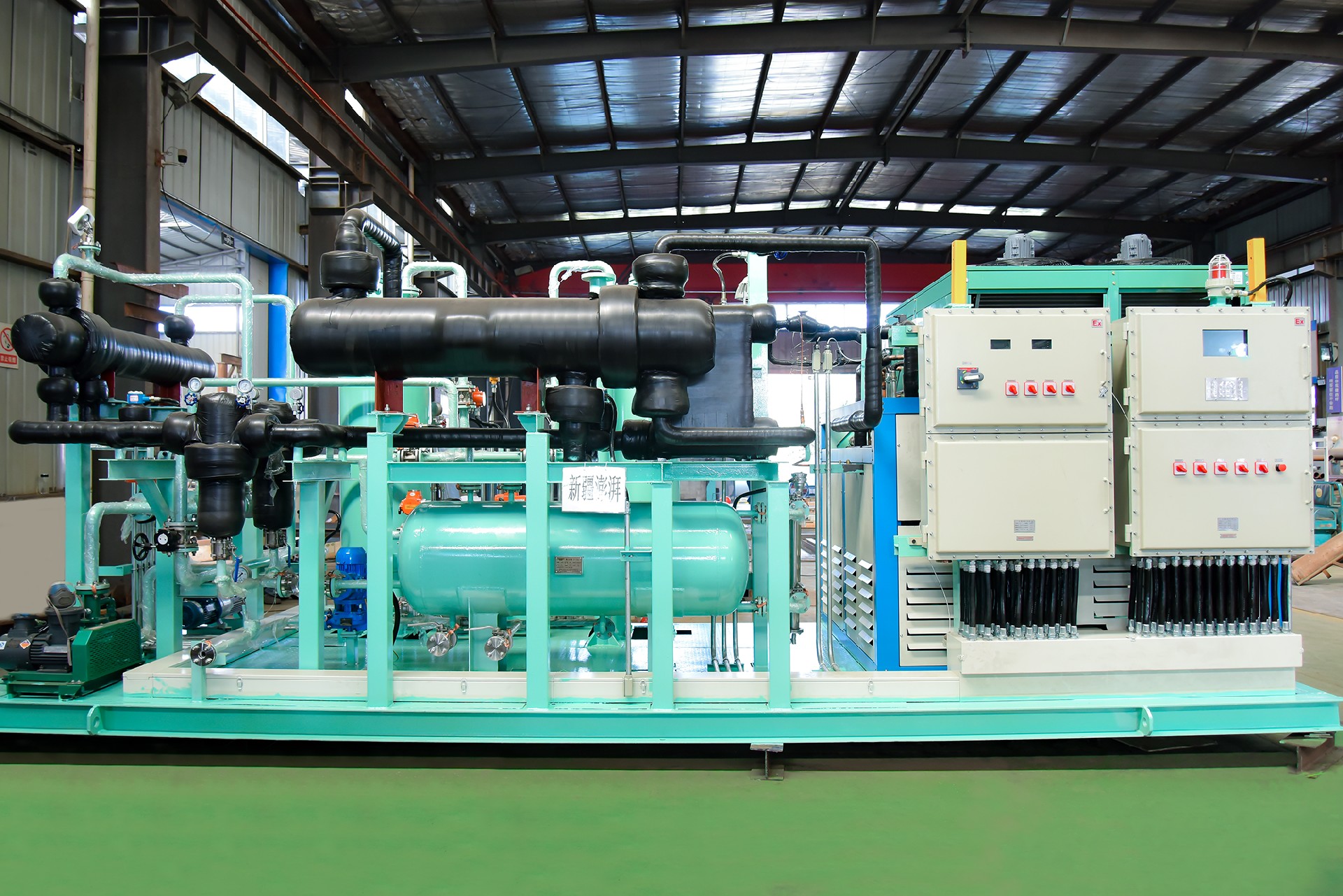

5. [RCO combustion method] process

The core principle adopted is high temperature combustion.

Advantages: mainly for high-concentration organic waste gas, thorough decomposition of pollutant components.

Disadvantages: high energy consumption, high operation requirements, large equipment volume, and certain safety risks.

6. [Concentrated recovery method] process

The core principle used is extraction and concentration.

Advantages: mainly for the recovery of valuable components from exhaust gas with a single composition, which has economic benefits.

Disadvantages: high operability requirements.

In practical engineering applications, microbiological methods can be considered for places with low air volume and low concentration. For exhaust gas with flammable nature, it is generally recommended to use spray pretreatment followed by other exhaust gas treatment processes.

EN

EN

RU

RU