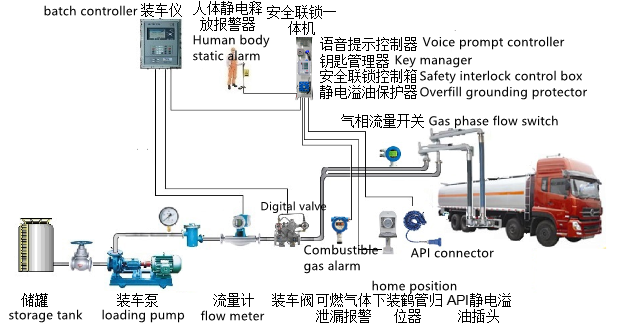

The filling process of the seven interlocking in the loading and unloa dingarea

Operation process before filling

1. After the vehicle passes the safety inspection, the on-site personnel guide the vehicle into the filling position (speed limit 5 km/h).

2. The driver stops the car and turns off the engine and turns off the main power supply of the car.

3. The operator places a parking warning sign in front of the tanker, and puts anti-skid sleepers on the wheels, confirms that the main power supply of the vehicle is turned off and receives the vehicle key.

4. The operator combines the vehicle key and the electronic key into the electronic control key box. (One interlock, electronic control key box interlock. If the electronic key is not inserted into the electronic control key box, the oil filling operation will not be triggered.)

5. The operator touches the human body static discharge device to discharge the human body static electricity. (Two interlocks, human body electrostatic discharge interlock. The operator does not touch the human body electrostatic discharge device, and the oil filling operation will not be triggered.)

6. The operator installs the two-in-one plug for electrostatic discharge and oil spill prevention. (Three and four interlocks, anti-static and anti-oil spill interlock. The plug is not connected or the contact is not good, and the oil filling operation will not be triggered. If the connector falls off or becomes loose during the filling process, the interlock will be triggered to terminate the filling .)

7. The operator installs the liquid-phase loading arm. (Five interlock, loading arm return interlock. If the loading arm joint and the tanker joint are not in place, then the valves of both parties cannot be opened and the oil filling operation cannot be carried out. The oil filling is completed, and conversely, if either side of the valve If it is not closed, the loading arm cannot be removed from the truck, thus effectively avoiding the phenomenon of oil running and oil leakage.)

8. The operator installs the gas recovery loading arm. (Six interlocking, interlocking gas phase flow detector. During the filling process, the oil and gas in the tank will flow through the detector along the pipeline. If the gas recovery pipeline of the vehicle is not clear due to the loading arm position or the vehicle, the detector cannot detect gas If the flow or flow value is too small, then the filling operation will be terminated. This avoids the pressure of the tank due to the improper gas line of the vehicle or the valve being not opened, and the tank rupture and oil spray due to the pressure of the tank. Splash, leakage, fire, explosion accidents.)

9. The operator swipes the card at the fuel delivery controller and presses the start button for loading operations. (An abnormality in any of the above six interlocks will cause the fuel delivery system to refuse or terminate the fuel delivery operation.)

10. During the loading process, if the on-site combustible gas concentration exceeds the standard, it will trigger the combustible gas detector to alarm. After the alarm exceeds 5 seconds, the system will automatically stop filling (7 interlock, combustible gas alarm interlock cut off.)

Operation process after filling

The operator removes the liquid-phase loading arm and the gas-phase recovery loading arm and returns them to their positions. (If it is not effectively connected with the home position, the interlocking control system will send out an audible and visual alarm.)

The vehicle stays in place for 3 to 5 minutes to fully discharge the static electricity generated during the filling process.

The operator removes the anti-static and overfill two-in-one plug and returns it to its place. (If it is not effectively connected with the plug returner, the interlock control system will send out an audible and visual alarm.)

The operator takes out the start key and the electronic key and closes the door of the electronic key box. (If the electronically controlled key box door is not closed, the interlocking control system will send out an audible and visual alarm.)

The operator removes the parking warning sign and non-slip sleepers.

After the operator checked the vehicle for no abnormality, the driver drove the vehicle out of the loading arm position (speed limit 5 km/h).

EN

EN

RU

RU