What are the materials of the fluid loading arm

What are the materials of the fluid loading arm?

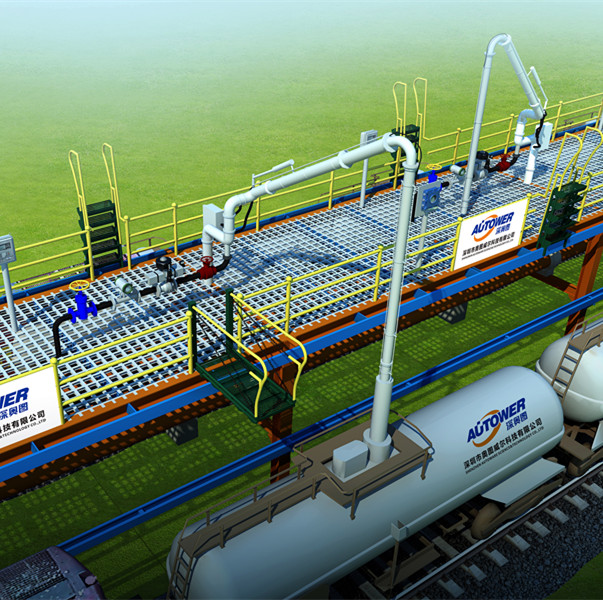

The loading arm is a device that is connected in series with the pipe by a rotating joint with flexible rotation and good sealing performance, and is used for liquid medium transmission between the tank truck and the trestle storage and transportation pipeline.The key components of the swivel joint are processed by precision CNC machine tools, with a built-in double raceway support structure, which is flexible in rotation, light and reliable. The outer ring is made of alloy steel, and the inner ring is made of stainless steel or PTFE lined to ensure that it can be used safely and reliably in high temperature, low temperature, and strong corrosive media.

The steel-plastic composite pipe of crane pipe conforms to the current chemical industry standards "Plastic Lining (PP, PE, PVC) Steel Pipes and Fittings" HG 20538-1992 and "PTFE Lining Steel Pipes and Fittings" HG/T 21562-1994. Crane pipe forgings should meet the requirements of the current national standard "Steel butt-welded seamless pipe fittings" GB/T 12459-2005,"Carbon steel and low-alloy steel forgings for pressure vessels" JB4726-2000, "Carbon steel and low-alloy steel forgings for low-temperature pressure vessels" JB4727-2000 and the current machinery industry standard "Stainless steel forgings for pressure vessels" The provisions of JB4728-2000.

Generally non-corrosive petrochemical liquid materials, usually high-quality carbon steel pipes are used.

It is necessary to maintain the purity of petrochemical liquid materials and prevent the mixing of rust. The loading and unloading arm pipes should be made of stainless steel pipes. If the liquid materials are directly used in the food industry, the loading and unloading arm pipes should also be made of stainless steel.

Principles for selection of loading and unloading arms for commonly used corrosive acid and alkaline materials:

1) Nitric acid: Stainless steel pipes or plastic-lined pipes should be used for the loading arms. If the drop tube is inserted into the tanker is long , the drop tube can also be aluminum pipe.

2) Glacial acetic acid: acid-resistant stainless steel (316L) can be used.

3) Sulfuric acid: 98% sulfuric acid and oleum use high-quality carbon steel pipes, dilute sulfuric acid (less than 80%): steel-lined PTFE pipes, steel-lined PVC pipes, steel-lined PP pipes, etc. should be used. If the drop tube needs to be inserted into the tanker truck, PVC pipe, PP pipe, PTFE pipe or glass steel pipe can be used to insert the drop tube.

4) Hydrochloric acid: Basically the same as dilute sulfuric acid materials.

5) Caustic soda solution (normal temperature): the loading arm adopts high-quality carbon steel pipe.

EN

EN

RU

RU